Our next destination on our lathe journey remains along the Mediterranean coast. France is highly renowned for its wine, gourmet cheese (Brie, Camembert, Comté, and countless other varieties of dairy creations, known to stimulate and occasionally even overwhelm one’s olfactory senses), crunchy baguette bread and various types of croissants, and picturesque villages along a vast labyrinthine network of small country roads with ridiculously low speed limits and steep fines for exceeding the posted speed limit by 1 kilometer per hour…!

Nobody speaks English out of principle and in order to be able to enjoy all that France has to offer in the form of culinary pleasures and treasures, you had better befriend one of the locals (and learn French to do so), as the opening times of restaurants defy any logic and are different from region to region. Museums and shops remain closed on certain workdays every month that are particular to each region, so insider information is required to be able to do anything there. Imagine being in gastronomic heaven, only to find out that you cannot actually get any food because it is the third Tuesday of September, so you drive on to the next village to be informed that you still cannot get any food because by now it is Wednesday, and in this region you could have gotten food on Tuesday!

It was presumably due to the aforementioned that back in the days when there was more of everything, certain individuals, trained in the fine ways of the screwdriver, decided that on the days when they could not obtain food, there wasn’t a much better way to pass the time than to manufacture disk recording lathes. Information pertaining to the French tradition of discographic contraptions is extremely scarce and exclusively limited to the linguistic traditions predominant in the country. In other words, you stand a better chance of being allowed to purchase a croissant on a Thursday than to find any information on French disk recording equipment in English.

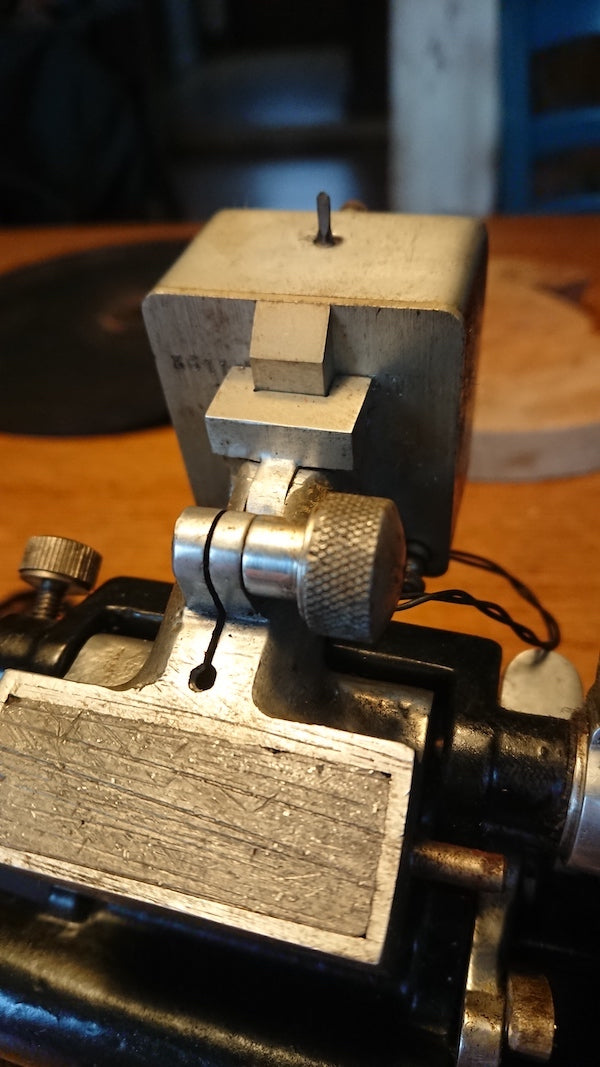

A cutter head mount for a French recording lathe.

One of the first French disk recording lathes I ever saw was called “Le Discographe,” with the initials “LD” appearing on various parts of the machine. After seeing a few of these lathes, I found out that LD actually stands for L. Dauphin, which I assume was the name of the manufacturer of the machine. I have encountered these machines in a few different configurations, with platter sizes ranging from 12 inches all the way to 14 inches. The turntable is idler-driven. The overhead lathe mechanism is fixed on supports on either side of the platter. The leadscrew is driven through a 90-degree angle-drive gearbox, but unlike American disk recording lathes, the input shaft is horizontally oriented, located on the left-hand side of the overhead and runs front to back, rather than to the side or straight down. This necessitates the use of a flexible driveshaft, similar to the flexible driveshaft used with Dremel tools. On the early machines I saw, this was connected to a pulley, on a vertical shaft behind the platter, driven by a belt connected to the platter. A rather long-winded approach, but it works, and offers plenty of space for modifications for adding electronically-variable pitch control, an idea which was surely unheard of at the time these machines were made.

There was also an LD-branded, monophonic moving-iron cutter head, similar in operating principle and design to the early American moving-iron designs, such as those by RCA, Audax and Fairchild.

Whether Dauphin was the surname of the inventor, or a somewhat esoteric reference to the French royal title of nobility, literally translated as “dolphin,” still remains an open question.

The Le Discographe lathes appear to have been made from the mid-1940s to the mid-1950s and apparently also included some models where the overhead mechanism was resting on a foot placed on the center of the platter and driven by the platter directly, in the same manner as most Presto and Rek-O-Kut lathes. From the mid 1950s onwards, the LD brand manufactured the Magnetographe series of magnetic tape recorders (tape machines), leaving the disk medium behind.

Another manufacturer of disk recording equipment in France was Poltz Freres. While I have encountered a few lathes and cutter heads over the years, I have never been able to find any conclusive information about the company. There are some references to “Poltz Bros” online, so it could have been a family business of some kind. Both the lathes and the cutter heads were very similar in design to those made by LD. The overhead mechanisms also featured the flexible driveshaft, which appears to have been a bit of a trend in France among disk recording equipment manufacturers.

Poltz Freres lathes installed upon Dual turntables.

Poltz Freres lathe overhead mechanism, with its flexible drive shaft clearly visible.

There was a time in history when French engineering was notable for innovative ideas. Up until the 1970s, French cars had a characteristic finesse, elegant design, and strange features, such as the hydro-pneumatic suspension system, complete with green, ball-shaped accumulators in the engine bay, on the Citroën DS, along with its overall futuristic body styling.

French tool manufacturers were also thriving during the same period. In line with most of the rest of the world, however, past the 1970s innovation gave way to more-of-the-same, mundane products. Modern French cars look very similar to any other cars, and there are no lathe manufacturers in France anymore. The innovative thinking does, however, still remain, in the difficulties encountered by the uninitiated while attempting to obtain food.

In contrast to the relative obscurity of LD and Poltz Freres equipment, disk recording lathes were also manufactured by someone who appears to enjoy celebrity status in France: Pierre Clement was a renowned engineer, known for his work in sound recording, broadcasting, and the motion picture industry, establishing these sectors in France and designing a lot of the early equipment needed to get things up and running. Born in 1906, he was already active in the film industry by the late 1920s. Pierre Clement lathes can be found in different sizes, shapes and forms, including some massively big machines that appear to be the only non-portable professional disk recording/mastering lathes made in France.

Some Pierre Clement lathes, branded “PC,” in line with what seems to have been the branding convention in France among lathe makers, appear to have been handcrafted prototypes, whereas others were probably made in greater numbers.

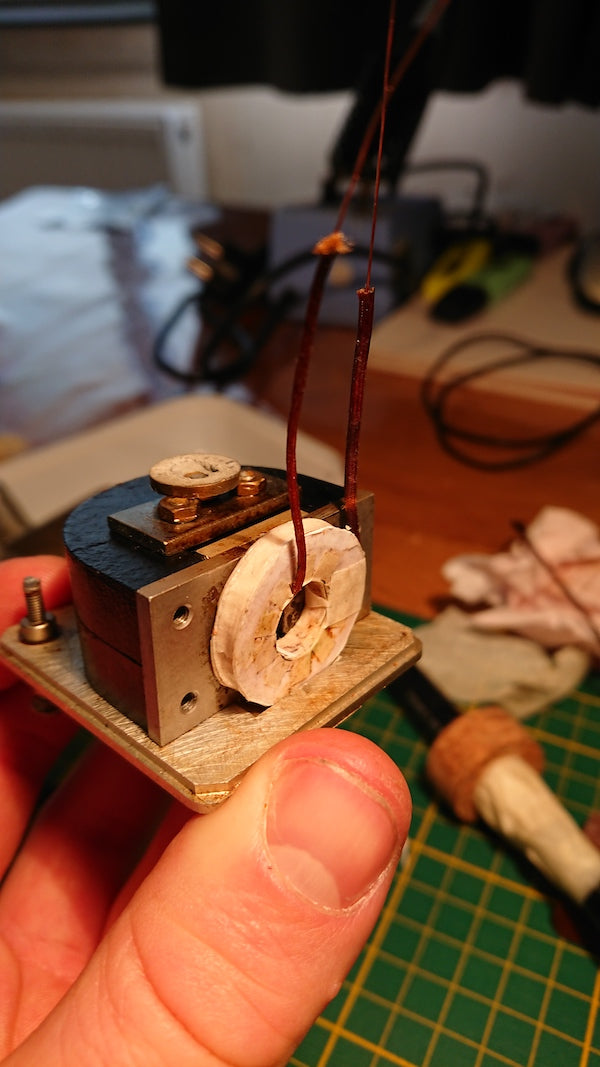

The bottom of a Pierre Clement cutter head.

Pierre Clement cutter head, internal details.

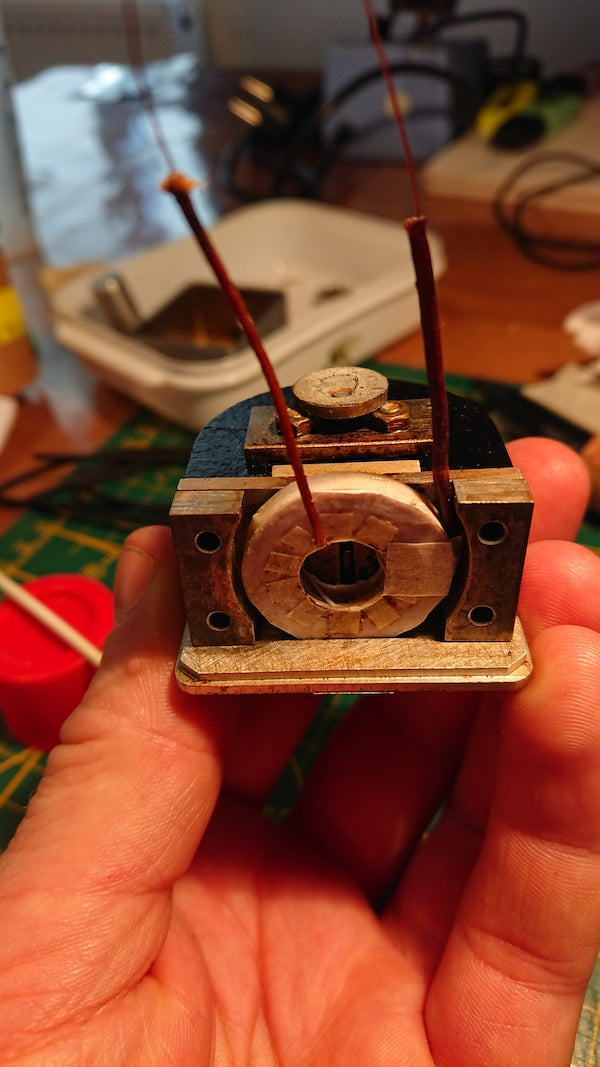

Pierre Clement cutter head, internal details.

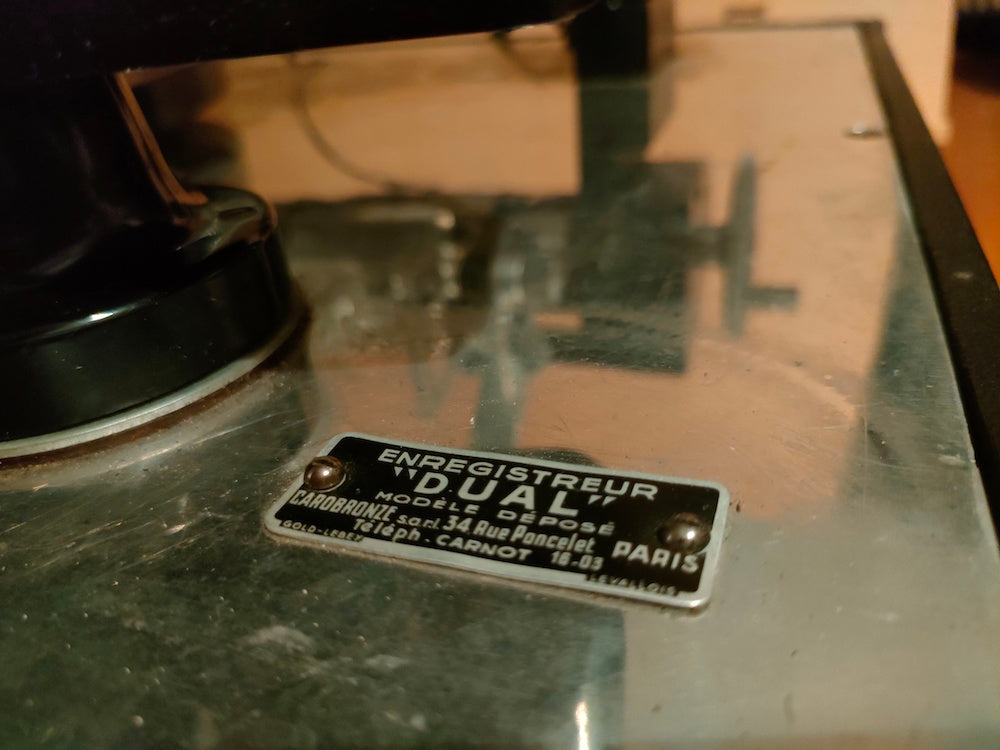

Pierre Clement himself was also involved with Carobronze, an importer of Dual equipment, manufactured by the Steidinger Brothers in Germany. While I have never come across any disk recording lathes manufactured by Christian and Joseph Steidinger, under their Steidinger Bros. or Dual brands in Germany, Pierre Clement appears to have made extensive use of Dual turntables and motors as a base upon which his disk recording lathes were constructed.

Pierre Clement cutter head.

Dual nameplate.

Top view of a Dual turntable and lathe mechanism with a Poltz Freres cutter head.

Dual motor drive.

France also had their own lacquer disk manufacturing and in fact, the Pyral company can be credited with having invented the nitrocellulose lacquer-coated blank recording disk, which became the industry standard, replacing wax blanks and vacuum sputtering with the process that is used all around the world to this day for the manufacturing of phonograph records.

Dual turntable with Poltz Freres mechanism and Pierre Clement cutter head.

Pierre Clement cutter head.

At this point, my dear readers, I must go get that Camembert out of the oven, as my nose tells me it is just about baked to perfection. The fresh celery stalks and raspberry chutney await by the baguette.

Header image: A Pyral stroboscope. Note the flexible drive shaft coupling. All images courtesy of Emile Wingert, Brother Sound, France.

0 comments