After our visit in Provo, we traveled via plane to Phoenix, Arizona – a distance of just under 800 kilometers. On the first evening, D’Agostino had invited us to his private home, where – Italian roots oblige – he wanted to demonstrate the qualities of his huge pizza oven. Some employees of Dan D’Agostino Master Audio Systems (short: DDMAS) collected us at the airport. The comparatively long drive to Cave Creek took us over the tricky urban highways of Phoenix, out into the rocky Arizona desert. I have to admit that I’ve always had a soft spot for roadways in the western United States: take a pencil and a ruler and connect two dots. Done!

The Peculiar Beauty of Arizona

Interestingly, Cave Creek is still part of the Phoenix metropolitan area. In actual fact, though, the loose settlement is already in the middle of the desert. The D’Agostinos’ house borders on a small valley (the associated creek has been conspicuous by its absence for years) and is surrounded by dozens of the typical saguaros, cacti that can grow to a cool 15 meters tall and more. If you were to trudge north from the terrace of the D’Agostinos, you could reach the Grand Canyon after four or five days, if you were lucky – you wouldn’t see many houses or roads along the way.

In short, the scenery could hardly be more picturesque: While we feast on the excellent pizza, we can hear the soft “feixing” of coyotes in the background. When I ask what exactly drew the D’Agostinos to the desert (they are originally from Connecticut), the host answers without hesitation: I never wanted to shovel snow again! Later, he notes that he has always been fascinated by the region. It’s wondrously beautiful here, he says – and everything tries to sting you.

Now for the Nitty Gritty

In case you’re not familiar with the legendary engineer’s story, Dan D’Agostino founded Krell in 1981 and was not only the owner and CEO there, but also played a major role in all the developments. The fact that high-performance amplifiers look the way we know them today is also thanks to him. While he was telling us about his career, D’Agostino unconsciously drew a connection to our previous stop: for his first trade show ever (CES), he shared a room with Dave Wilson’s startup, which was also still young. In the 2000s, D’Agostino then brought investors on board, who rudely kicked him out the door in 2009 after a dispute over the company’s future course…

This could have closed the D’Agostino file. But he is not one to take it easy. Only a short time after he left Krell, the busy tinkerer started to grow itchy fingers. Like all engineers of his caliber, he was annoyed by a thousand little things that he could have done better (or more consistently) at Krell. With a little distance, he was bothered by the technically sober appearance of many devices. At the time, he recalled, he was so immersed in his circuits that he more or less regarded external appearances as a “necessary evil.”

Dan D’Agostino Master Audio Systems

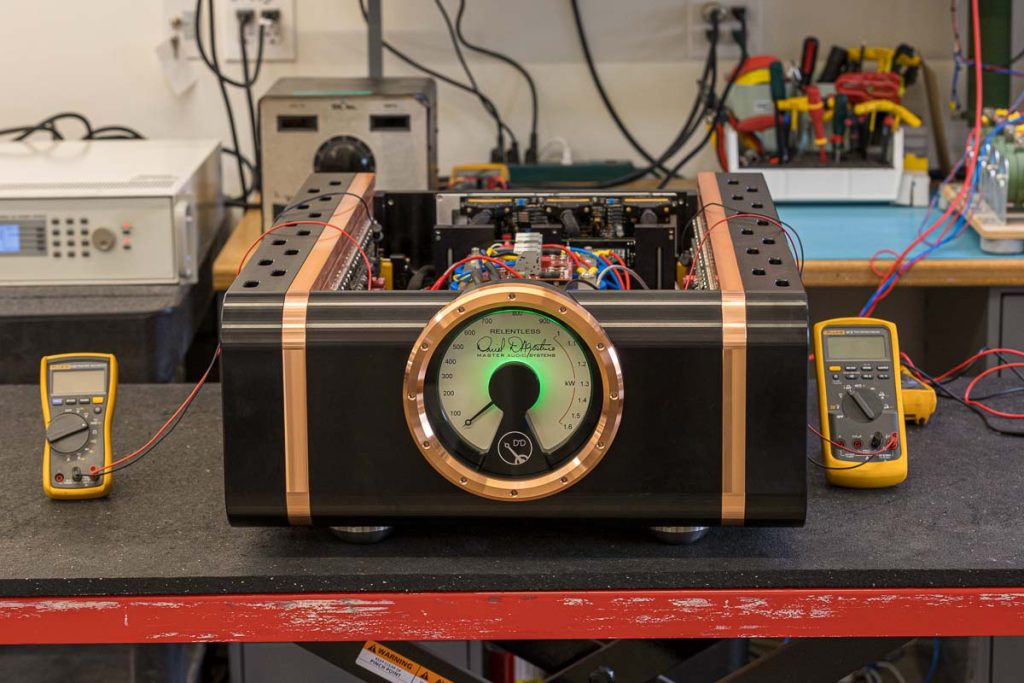

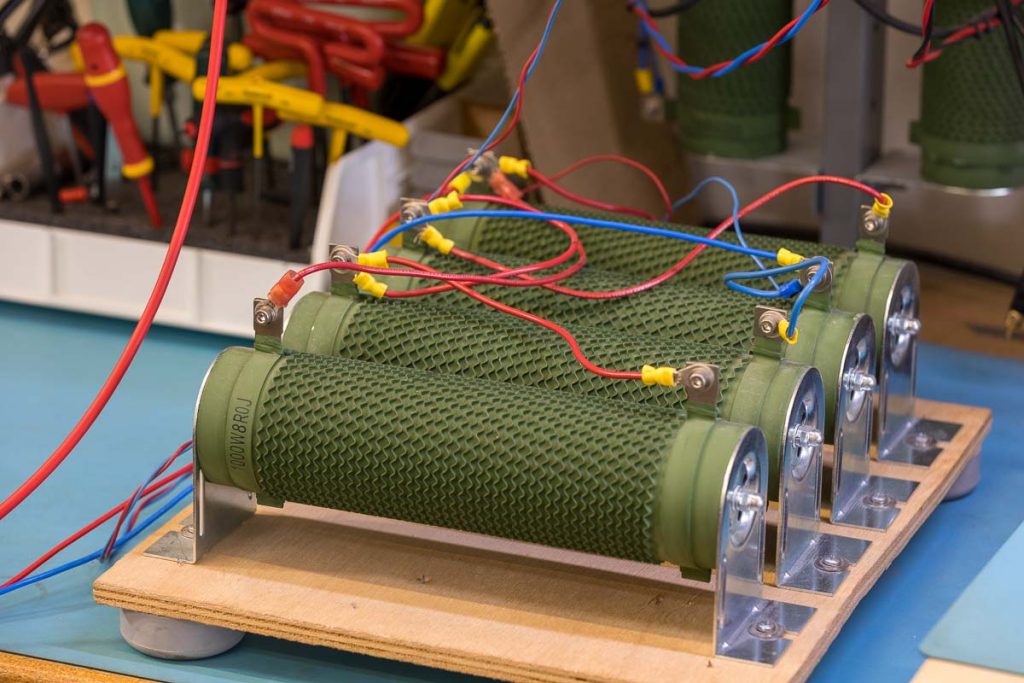

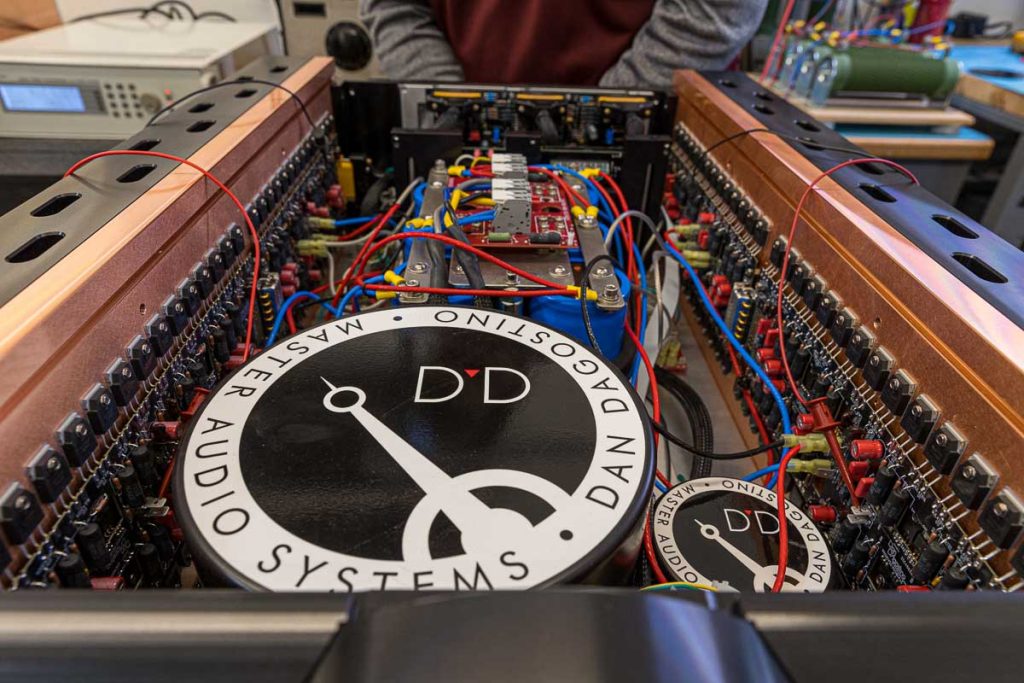

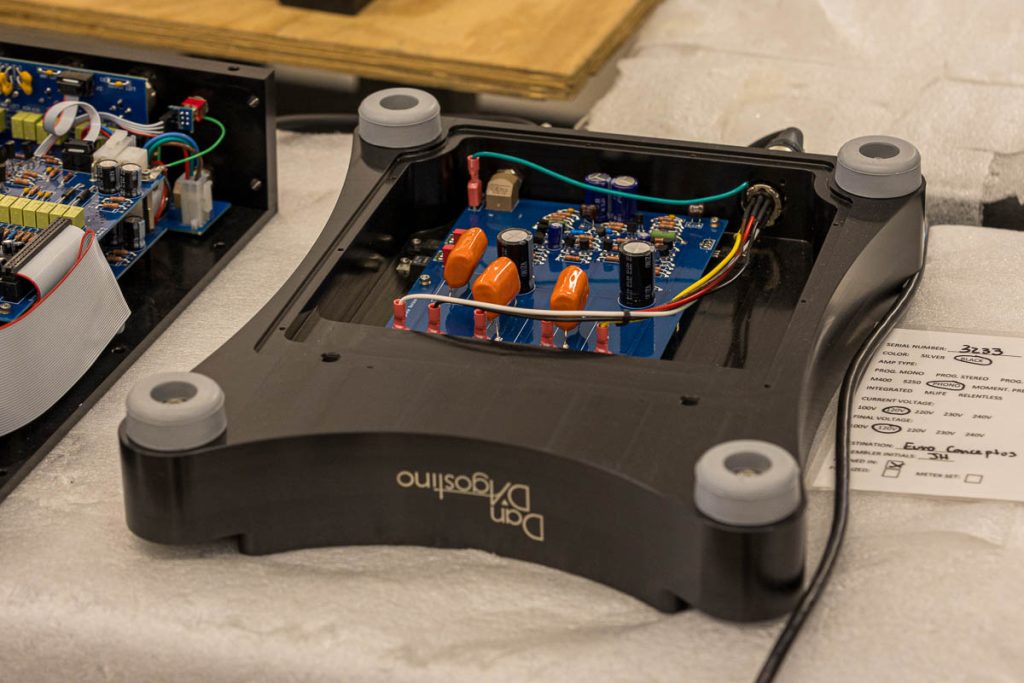

So he founded a new company with a noticeably sharper profile: Dan D’Agostino Master Audio Systems. 2011 was the year. Under this brand name, he and his team manufacture just three families of equipment. However, each of these series claims to be among the absolute superlatives in its respective class. To back this up, D’Agostino demonstrated to us the next morning in his factory how one of the huge Relentless monos blows 1,600 watts into the audibly groaning load resistors – and that (I hope you’re sitting down) at 8 ohms! After the demonstration, the power amp’s electrolytic capacitors (totaling about 600,000 microfarads of capacity) were so saturated with voltage that an employee had to carefully discharge them with a light bulb.

The mono versions of the “smaller” Momentum and Progression models still manage 800 and 1,100 watts into 4 ohms each. In a country where V8 engines with a displacement of 7 liters are sometimes called “small block,” such muscle play is a matter of honor. In fact, however, the power show has a valid background: As a developer who has been washed with all waters, Dan D’Agostino knows that an amplifier is only as good as the complex load it is working on allows it to be. To get a handle on even the trickiest loudspeaker, you need handsome power reserves. The real art, he says, is to design the beefy amps in such a way that they are not crushed by their own power. Thanks to the know-how he has acquired over decades, D’Agostino succeeds in tuning even the mighty Relentless amplifiers musically and in terms of fine dynamics.

No Compromises

Analogous to Wilson Audio, he increasingly relies on in-house manufacturing. Just recently, his manufactory – the company spans a single large room – was upgraded with an improved automatic soldering machine. This reduces dependence on service providers and speeds up quality control. After a lengthy warm-up period, we witnessed molten solder flowing through the inside of the machine. To me, it’s nothing short of a miracle that circuit boards and components don’t turn into wobbly goo on their way through this oven. They do get hot, of course. So much so, in fact, that after the populating process, they have to be placed on a cooling rack with gloves on.

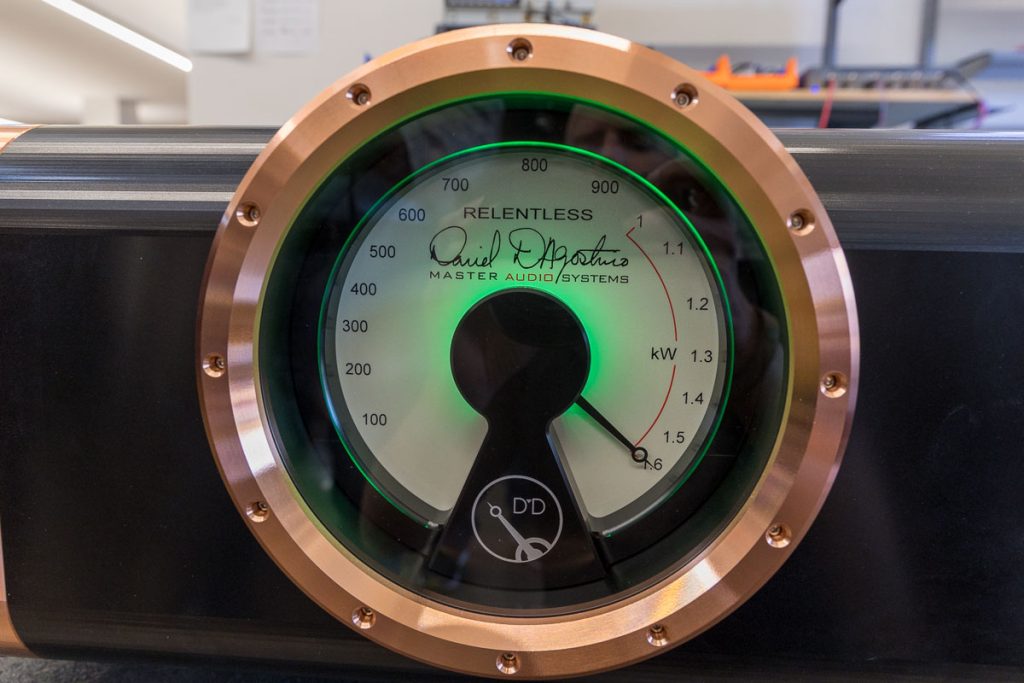

A little later, we discovered another parallel to Wilson Audio: D’Agostino is downright obsessed with the workmanship, design and finish of his cabinets. In a clear departure from the technical feel of Krell, he sought more imaginative shapes. After some experimentation, he found elegant devices with rounded faces, in the center of which sits an illuminated power indicator. Of course, you know these machines: they have been among the most photographed objects at Hi-Fi fairs since their birth (the Momentum series made the beginning). I myself can’t count how many pictures I have of the DDMAS portholes.

Limitless Sound Meets Limitless Durability

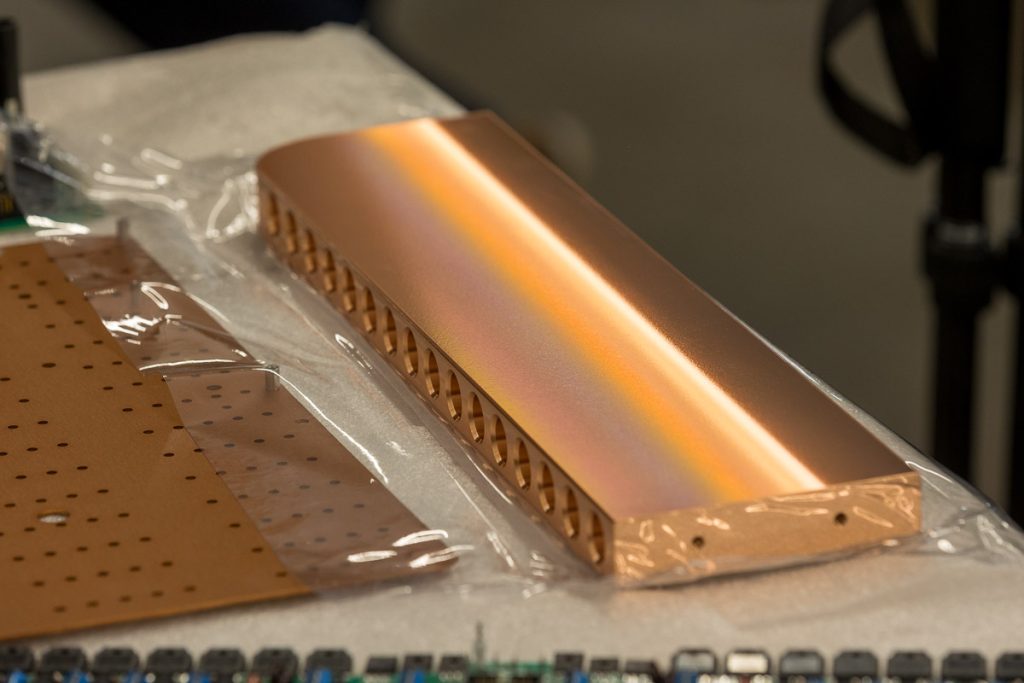

The flanks of the Relentless and Momentum amplifiers are protected by massive copper heat sinks. Finishing the frighteningly heavy components was pure hell, as Dan D’Agostino explained to us. In the beginning, he had simply ordered any copper plates. But at the slightest touch, there were oxidized fingerprints on the metal. After years of searching, he found a refiner who could seal the components without reducing cooling performance. We remember: Since the amplifiers have almost insane performance data, cooling capacity is a decisive factor at D’Agostino. After all, the machines are supposed to work anywhere in the world and in any season.

Shortly afterwards, the owner drew our attention to a small group of employees that we hadn’t noticed until then. Four employees were sitting at a workstation, quietly soldering away at circuit boards with the utmost concentration. Every now and then, one of them would get up and help himself to a rack of colorful cable reels, cut some strings, and then disappear back to his seat. “This is where the real magic happens,” Dan commented on the scene. The workers do all the prep work as well as soldering that can’t be done with the machine. They prepare the final assembly of the components and check every connection. Here, too, DDMAS is uncompromising: amplifiers of this (price) class must function absolutely maintenance-free.

Dan D’Agostino’s “Porthole”

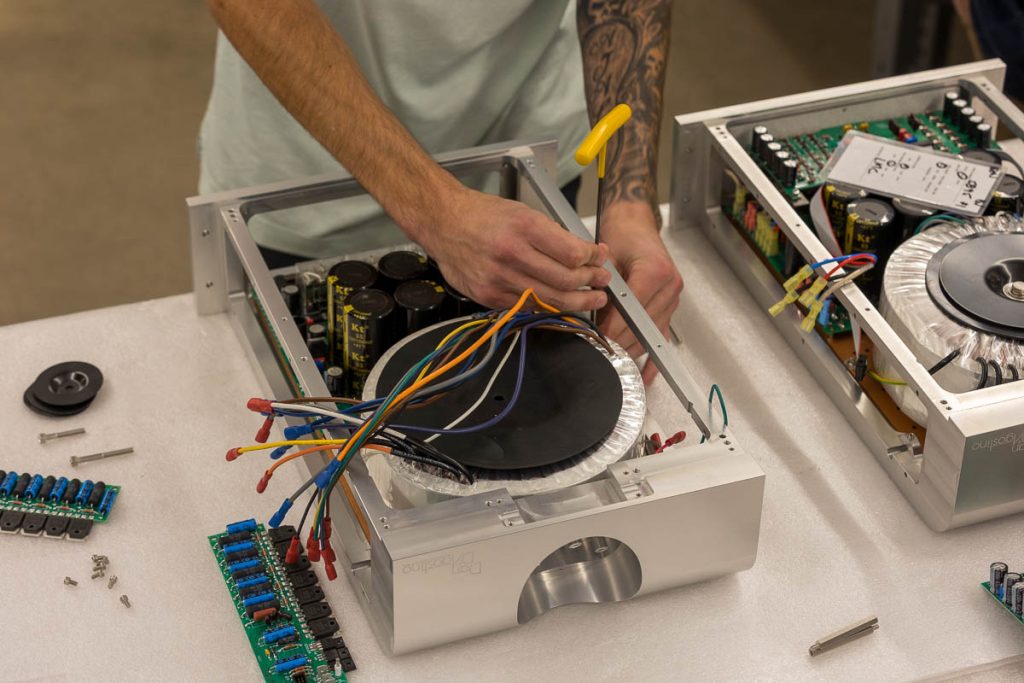

There’s no need to worry about durability, even with the various designs of the iconic power displays. A staff member demonstrated to us how the portholes of the Relentless power amps are assembled. Step by step, he joined the aluminum parts together. They were prefabricated by a supplier with such precision that they fit together seamlessly and effortlessly. The result weighed what felt like five kilograms and could hardly be taken apart. When we asked if he could repeat the process for some photos, he simply assembled another display.

Finally, to conclude our tour, Dan D’Agostino took us to an area of his manufacture where we were able to take a look at the inner workings of the new Relentless preamplifier. The three-part colossus consists of two separate mono preamps connected via a central control unit. To assemble the precious building blocks, D’Agostino enlisted the help of two employees. Alone, one hardly seems to be able to lift the massive segments.

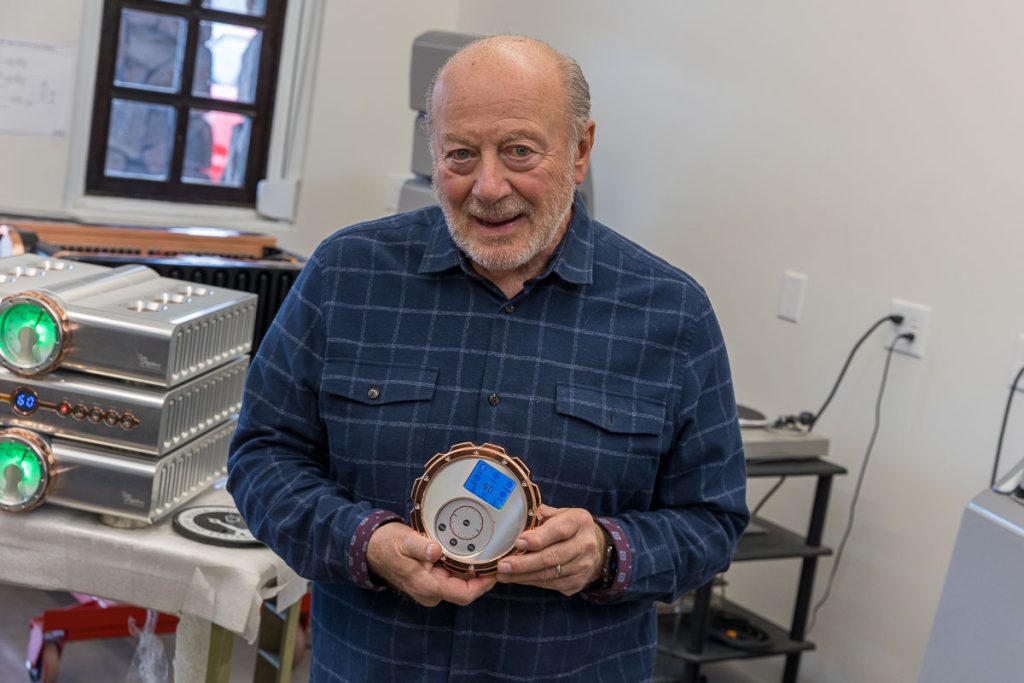

Source Ahead

By the way, the brand is venturing further and further bridges to the source: like the integrated amplifier of the Progression family, the exclusive preamplifier is available with a DAC and an optional streaming board. There is also a phono preamplifier, which is derived from the excellent equalizer of the Momentum series, which Dan introduced to us shortly thereafter. The Phonostage must be one of the most jam-packed “analog workstations” on the market: Four systems can be connected (2 x MM and 2 x MC), all finely tunable.

In the evening we finally had the opportunity to listen to Dan D’Agostino’s creations. The developer had asked us again to dinner at his house; this time we had steak. In his living room, he runs a Relentless system on Wilson Audio’s Chronosonic XVX. DDMAS President Bill McKiegan, with whom D’Agostino had previously worked at Krell, walked us through the demonstration. The absolute highlight was the recording of a brass ensemble – effectively punctuated with timpani beats. As if the D’Agostinos’ living room had no walls, the brass played with sheer incomprehensible breadth and depth. The sound system clearly brought out the finest nuances and, for all its transparency and resolution, possessed a wonderfully silky timbre. Incidentally, this was a track called “Olympic Fanfare” by the National Symphonic Winds (CenterStage). A recording made by Dave Wilson.

Breathtaking Performance

Even more than by the excellent live recording, I was thrilled by the fact that the system worked at all. Truth be told, the combination of Relentless and Wilson Audio’s mighty XVX is actually oversized for the room, with the speakers right up against the wall. Dan D’Agostino admits that he himself was amazed at how good the room sounds. They had tried many positions for the speakers, but they were either worse or destroyed any livability. The secret was revealed, he says, when he measured the room with a laser for a minor renovation: turns out the small finca [country estate] is (visually imperceptible) all crooked and skewed. There are virtually no parallel walls. Now that’s lucky…

All images courtesy of Carsten Barnbeck.

0 comments