Copper has an exchange program with FIDELITY magazine (and others), where we share articles between publications. Here we are honored to present an article from FIDELITY about a tour of the Wilson Audio factory.

Hamburg-based distributor Audio Reference invited us to a meeting with Daryl Wilson and Dan D'Agostino in December. This is the first part of our journey through the "Wild West" of the USA.

At the beginning of our trip was a rather sleepy group of journalists. Coming from different directions, all participants met in Amsterdam at about 7 o'clock in the morning. A big Delta Airlines plane then took us to Salt Lake City, from where it was only a short drive to Provo in the south. The "little town" sometimes gets lost on maps next to the significantly larger State Capitol, Salt Lake City. With a metropolitan population of 670,000, however, Provo is not exactly a tiny hamlet. And with a mean altitude of 1387 meters above sea level, frosty temperatures are all but guaranteed in December.

There are mountains, too – and not too few of them!

There are mountains, too – and not too few of them!

The first official appointment followed the next morning at the Wilson Audio (WA) corporate complex. Daryl Wilson, son of company founder Dave A. Wilson, who passed away in 2018, did not miss the opportunity to personally receive the visitors and, after a brief run-down of the schedule, guide them through the spacious factory halls. Besides Wilson himself, we were also joined by brand ambassador Peter McGrath, who had travelled here from Florida. He didn't want to miss the opportunity to finally welcome visitors to the manufactory again after such a long time.

X-Material and the Likes

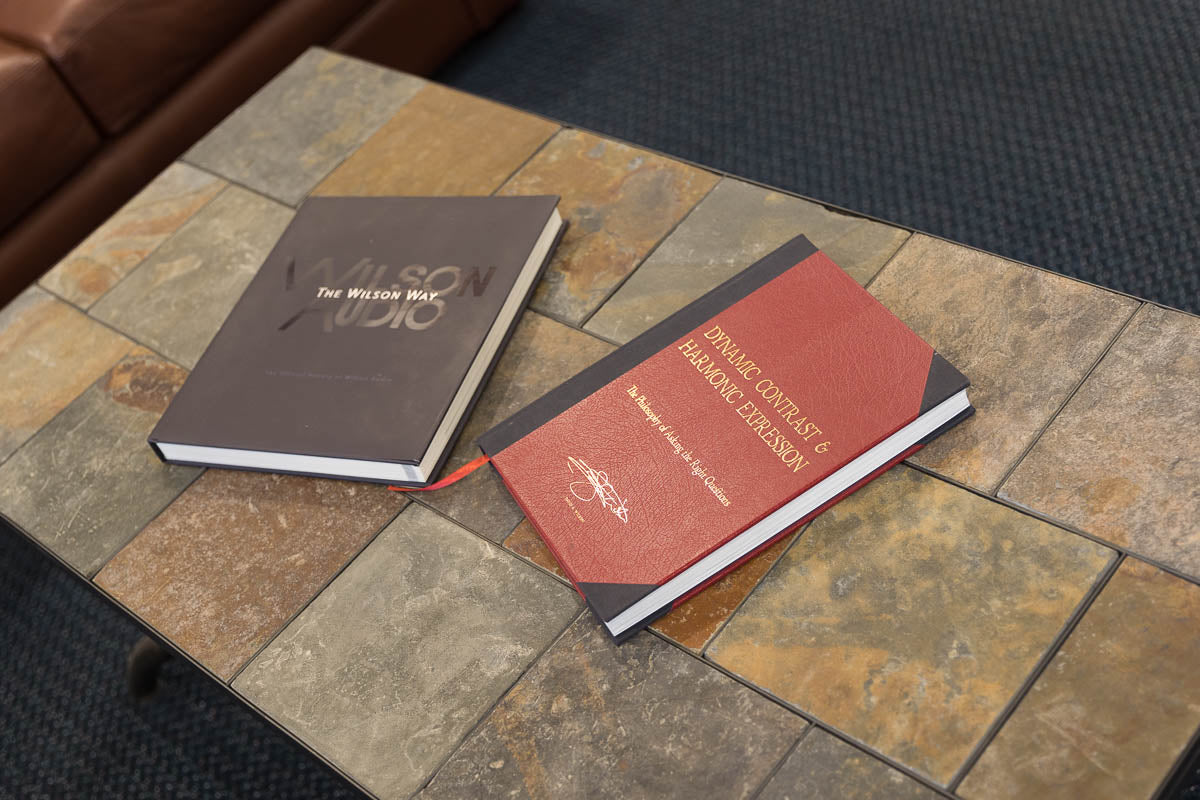

We have already reported several times about what is quite likely the most important American loudspeaker manufacturer and told the story of the company from different angles. You'll find the most important articles linked below. As is well known, the beginnings of Wilson Audio can be traced back to 1974. And, ironically, not with a loudspeaker, but rather turntable. Since the birth of WAMM in 1976 at the latest, though, the brand name has been firmly linked to the term "high-end": Dave Wilson was not only uncompromising in the processing of his unique works of art, he was also among the first (and most consistent) developers to think about aspects such as acoustic timing.

X and V and K and…Sales manager Trent Workman explains the properties of all the varieties of composite material.

Nevertheless, barely 10 minutes after our arrival, Daryl was able to close one first educational gap (of mine): Until now, I had assumed that the mysterious "material" of the Wilson speakers was a specific variety of artificial stone. But I was wrong: Under pseudonyms such as K-, X- or V-material, the manufacturer processes several composite materials based on phenolic resin that differ noticeably in weight, density and thus also in their properties and resonance behavior. Sales manager Trent Workman illustrated this to us with a few material samples that sounded noticeably different when knocked on.

Exclusivity shows in the details: Even the grille frames are made of the resin compound, as Workman explains. The material waste when producing these is downright absurd.

Precious Stuff

The real secret is to use the right materials in the right places. The "softer" X and V variants, for example, are suitable as damping material and vibration absorbers. The extremely hard K material, on the other hand, is the first choice for internal bracing or bass cabinets. There are no set-in-stone rules, however, since the behavior of the panels changes with their size and the recipe of one loudspeaker cannot be transferred to another without further ado. Decades of experience make it easier to work with the materials; whenever a new variant comes onto the market, it is at least tried out. And one piece of information on the side, which was also new to me: Even the support frames of the fabric-covered speaker covers at Wilson Audio are made of the precious material.

Daryl Wilson holding a raw slab. You can already see that this one is going to be a carrier piece for a midrange/treble unit.

Daryl Wilson holding a raw slab. You can already see that this one is going to be a carrier piece for a midrange/treble unit.

In one of the countless aisles, we discover a whole stack of freshly delivered slabs, which Daryl took as an opportunity to explain the prices of his speakers, which can be exclusive indeed. Even the smaller of the massive slabs cost the company over $500 to purchase. Even simply constructed speakers like the comparatively tiny TuneTot require six of them. Despite computer-controlled cutting of the material, the waste is enormous. And so is the processing effort. As our tour continued, we stopped in the milling and assembly hall. Here, two huge machines are incessantly busy shaping the composite. Their diamond-hardened milling heads have a maximum service life of two hours with the unruly material. After that, they can be sharpened by a service provider and, after another two hours of use, they finally go into the recycling bin - we were able to examine a few drums of used milling cutters right in the hall.

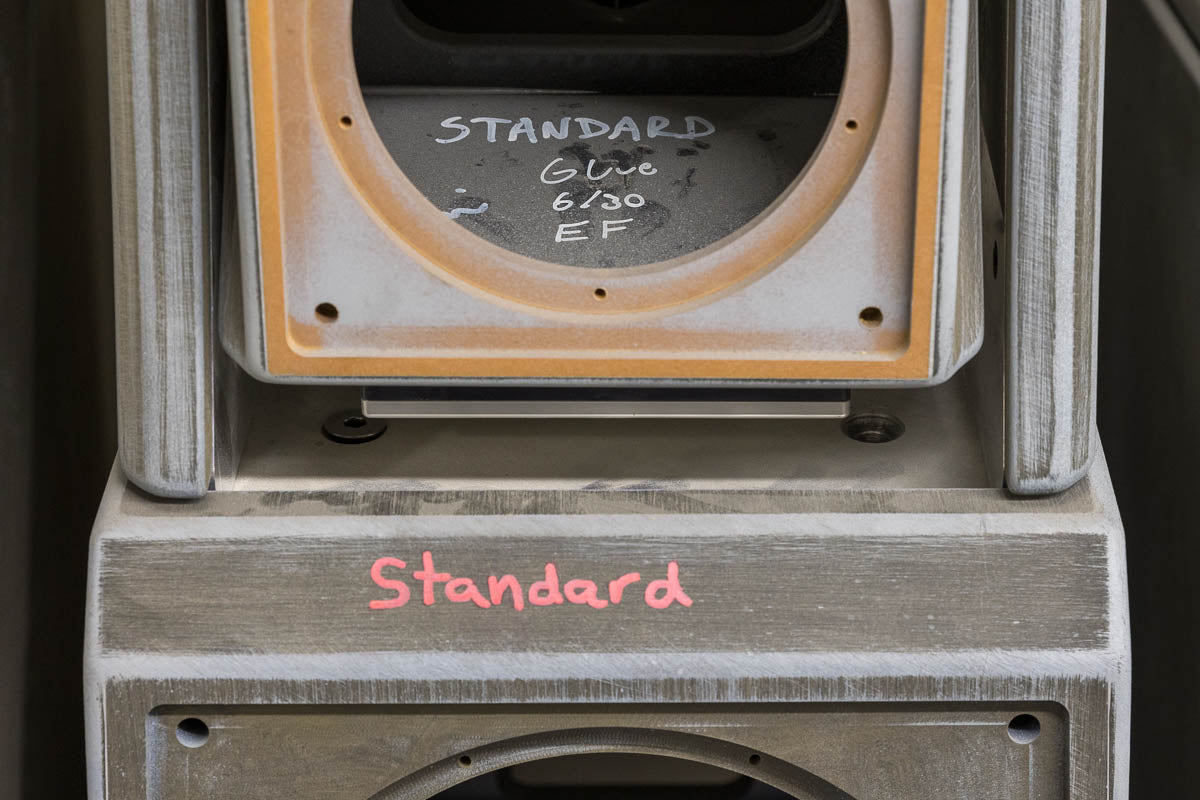

“I am the standard” – and this Alexia V means it: one of the hallways is lined with type samples of various loudspeaker heavyweights. When in doubt, the employees can take measurements here to make sure everything is to spec.

“I am the standard” – and this Alexia V means it: one of the hallways is lined with type samples of various loudspeaker heavyweights. When in doubt, the employees can take measurements here to make sure everything is to spec.

Daryl Wilson uses the aforementioned type samples to show us how proverbially “rough and ready” the WA enclosures look straight after assembly. At least the excess glue has been sanded down.

Daryl Wilson uses the aforementioned type samples to show us how proverbially “rough and ready” the WA enclosures look straight after assembly. At least the excess glue has been sanded down.

Milling And Gluing

In the immediate vicinity of the machine park, two employees were busy transforming the cut panels into the bass enclosure of an Alexia V. The speakers are completely glued. This is precisely where the manufacturing process of a Wilson Audio speaker changes from CNC precision work to a manufactured product: The two employees meticulously checked the result of each individual gluing, placing marks here and there for the coming processing steps. No sooner had they finished the bass cabinet than they signed the component at designated positions inside. Each individual production step is documented and noted on the speaker. From the first assembly to the final polish, quite a few signatures come together...

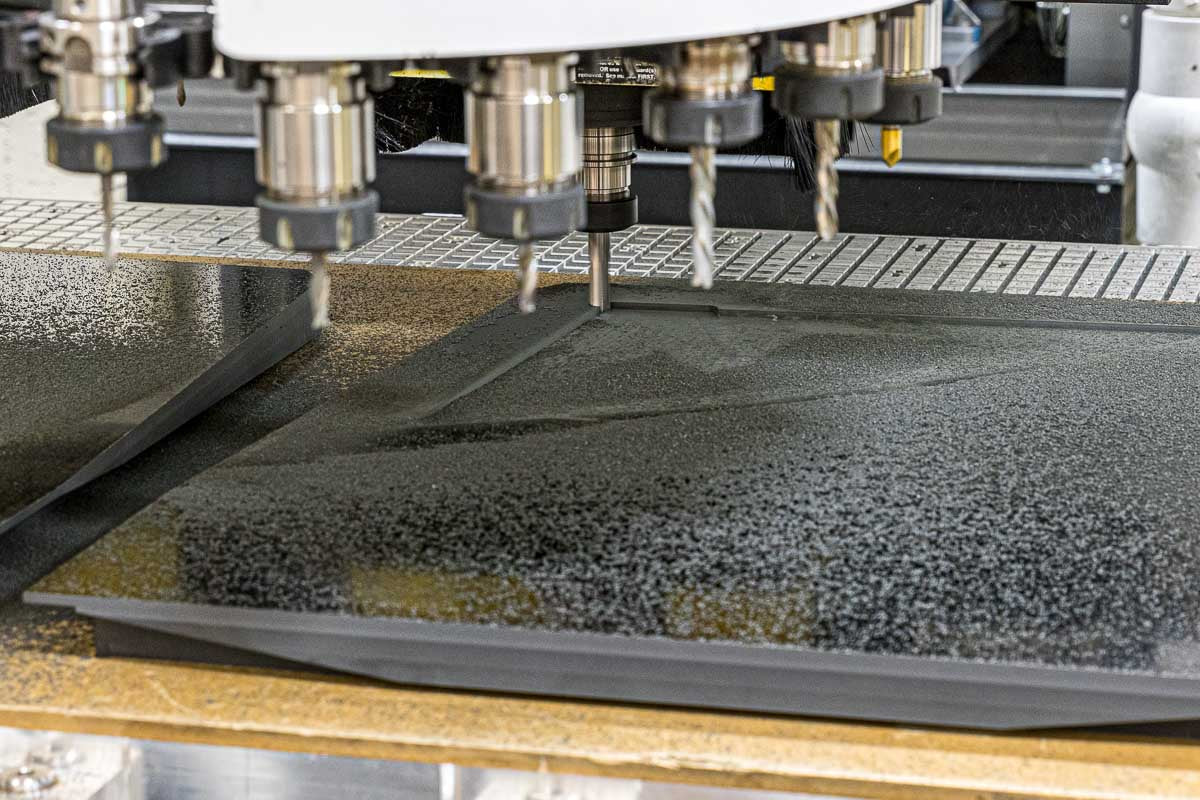

Making of a legend: Every Wilson Audio loudspeaker begins its life on one of these CNC machines.

Making of a legend: Every Wilson Audio loudspeaker begins its life on one of these CNC machines.

A plethora of bits allows for a wide range of routing jobs. They all have one thing in common though…

…after two hours of hard work…

…after two hours of hard work…

…it’s "off to the bin." Every single one of these diamond-coated bits costs several hundred dollars.

…it’s "off to the bin." Every single one of these diamond-coated bits costs several hundred dollars.

The next stop we made was the preparation for the paint shop. In this special sanding room, the still comparatively rough cabinets are brought into shape and smoothed. A whole team of employees removes protruding edges and glue residue. Since the inaccuracies can vary greatly, they have a sometimes obscure park of sanding machines and jigs at their disposal for this purpose, which they use to prepare the raw bodies for paint application.

This is what the end result looks like. The different colors of the pieces represent the various material formulations.

This is what the end result looks like. The different colors of the pieces represent the various material formulations.

You can hardly tell this by looking at the picture, but these two employees are buff like top-level athletes. The material is nearly as dense as natural stone, and the enclosure panels of an Alexia V are pretty damn big.

You can hardly tell this by looking at the picture, but these two employees are buff like top-level athletes. The material is nearly as dense as natural stone, and the enclosure panels of an Alexia V are pretty damn big.

A closer look at Wilson’s mechanized glue gun…

A closer look at Wilson’s mechanized glue gun…

… and here is the still-unsmoothed result.

… and here is the still-unsmoothed result.

Bringing Color To The Game

Wilson Audio is notorious for its outstanding finishes, and we can now see why: each component of the speakers - most speakers, after all, consist of several segments - is primed, sanded, painted, sanded, painted again, sanded, and so on. Finally, the segments are polished, where they are again given a deep, high gloss finish in several steps. Several weeks of work go into the newer effect paint variants in particular, as the paints have to rest again and again for days - in some cases even weeks - to cure. A particular challenge was to construct the building complex in such a way that the dusty sanding shop and the painting area interlock directly without interfering with each other. This is made possible by a separate annex with high-performance ventilation systems and an air-conditioned rest area where the coatings can cure in perfect peace.

After the assembly, it’s off to the sanding chamber, where the excess glue is removed and the cabinet shape perfected.

In a loudspeaker of this class, everything needs to be spot-on. The enclosure gets the same treatment inside and out.

In a loudspeaker of this class, everything needs to be spot-on. The enclosure gets the same treatment inside and out.

Surfaces being polished until smooth as a baby’s bottom.

Surfaces being polished until smooth as a baby’s bottom.

Stating that the work at the sanding shop is a huge mess is putting it mildly.

Stating that the work at the sanding shop is a huge mess is putting it mildly.

Directly after this area, we were introduced to the final assembly, where we could for the first time lay our eyes on drivers and electronics. Half a dozen employees were busy making cables. Wilson Audio produces all the internal wiring itself. This is the only way to ensure that all connections achieve the required quality. The same applies to the components of the complex (and sometimes huge) crossovers. In order to become more independent from the selection and quality of suppliers, the company recently acquired its own capacitor production. The production takes place in some adventurously complicated-looking machines. The wound coils are then sealed with various glazes and vibration damped.

Next stop, the paint shop. Daryl Wilson apologized for this sight: the protective foil hadn’t been replaced in three days.

Next stop, the paint shop. Daryl Wilson apologized for this sight: the protective foil hadn’t been replaced in three days.

The first primer coat is nearly completely removed by hand. Its only purpose is to fill in any minute irregularities in the surface.

The first primer coat is nearly completely removed by hand. Its only purpose is to fill in any minute irregularities in the surface.

It’s only after a second coat of primer (and subsequent sanding, of course) that color is brought into the game. In this case a vibrant red.

Still a bit pale around the nose: The lacquer takes days to cure – the peeps at Wilson Audio aren’t fans of artificially accelerating this process. Additional layers eventually provide for the desired saturation and depth. Meanwhile…

… you guessed it: bout after bout of sanding and polishing.

Final inspection: Can you spot any imperfections here? We certainly can’t – much unlike the WA pros with their highly trained eyes. For this particular cabinet it’s (almost) back to square one.

Final inspection: Can you spot any imperfections here? We certainly can’t – much unlike the WA pros with their highly trained eyes. For this particular cabinet it’s (almost) back to square one.

In-House Development

At the end of our tour, we took a short trip to the development department. In a small "infernal chamber" we experienced the effort Wilson Audio puts into its drivers. Some bass drivers were undergoing endurance tests, others were just being prepared for this procedure. To my surprise, I also spotted some driver variants that Wilson Audio does not (yet?) use in its speakers. Obviously everything is tried out. We got to know a particularly cute detail just a few rooms away: WA owns several 3D printers that are used for "prototyping". Tiny to medium-sized speaker studies can be found everywhere in the development: models of the Sasha DAW, dinky Alexias, filigree versions of the XVX and so on.

Intriguing insights into the capacitor production: Wilson Audio wanted to become less-dependent on suppliers in addition to demanding access to parts of extraordinary quality. After the winding process, the capacitors are meticulously sealed, thus “pacifying” them to a standard way above what you’ll usually find in the industry.

Intriguing insights into the capacitor production: Wilson Audio wanted to become less-dependent on suppliers in addition to demanding access to parts of extraordinary quality. After the winding process, the capacitors are meticulously sealed, thus “pacifying” them to a standard way above what you’ll usually find in the industry.

The winding process is done on this mind-boggling machine. Can you spot the metal film of which the cap is made?

The winding process is done on this mind-boggling machine. Can you spot the metal film of which the cap is made?

Dinky: miniature Wilson Audio speakers.

Dinky: miniature Wilson Audio speakers.

Also, drivers that aren’t to be found on any Wilson Audio speaker. The R&D department gives every part a shot.

Also, drivers that aren’t to be found on any Wilson Audio speaker. The R&D department gives every part a shot.

Jokes that only audio engineers understand are, of course, a staple.

Jokes that only audio engineers understand are, of course, a staple.

During our visit, Audio Reference CEO Mansour Mamaghani (r.) pointed a design flaw in the rock solid wooden cases out to Daryl Wilson. Don’t be fooled by his stern look though: The flaw was anything but serious. Obviously, Daryl Wilson is set to correct it anyway.

During our visit, Audio Reference CEO Mansour Mamaghani (r.) pointed a design flaw in the rock solid wooden cases out to Daryl Wilson. Don’t be fooled by his stern look though: The flaw was anything but serious. Obviously, Daryl Wilson is set to correct it anyway.

Over Coke, water and salad, we then had the opportunity for some small talk. Daryl told us about the challenges of the Covid period, which his company had mastered satisfactorily. In contrast to many other companies in the vicinity, Wilson Audio did not have to lay off any employees. He said that in-house component production in particular proved its worth during this time, as it reduced dependence on supply chains.

His father left him a healthy company with both feet firmly planted in the hi-fi industry. He himself (Daryl had been involved in all developments for over twenty years) has the traditional series well under control. Above all, however, the approaching anniversary makes him pensive - in 2024 WA will turn 50 years old. It is a huge challenge to make Wilson Audio fit for the coming decades. And the hi-fi market is currently undergoing a profound change, which makes the planning of future products considerably more difficult...

Daryl Wilson in what must be the most playful CEO’s office we’ve ever seen. The book in front of him is actually his laptop.

Daryl Wilson in what must be the most playful CEO’s office we’ve ever seen. The book in front of him is actually his laptop.

There’s plenty of model aircraft like this legendary Bell X-1 flown by Chuck Yeager…

…and the listening is done over Nagra equipment.

…and the listening is done over Nagra equipment.

Daryl Wilson Presents the WAMM

The rest of the day, however, was once more dedicated to the company tradition. Daryl Wilson invited us to his parents' house, where we met his mother Sheryl Wilson. The Wilson's living room is still the best place to experience the mighty WAMM Master Chronosonic. After all, the colossus was developed within these four walls. Over the next few hours, the speakers with their two subwoofers gave us an impression of true elemental forces. Peter McGrath demonstrated some of his own recordings to us, which conveyed a glorious live atmosphere and showcased the sheer limitless soundstage of the WAMM. Daryl then revealed to us that the homely room was constructed to the specifications of a recording studio. Although the room appears rectilinear, there are no parallel walls, he said. Invisible absorbers are built into the ceiling.

For scale: Daryl Wilson next to the original WAMM, the company’s first loudspeaker from 1976.

For scale: Daryl Wilson next to the original WAMM, the company’s first loudspeaker from 1976.

And here he’s standing next to the WAMM Master Chronosonic, the latest incarnation of the top-of-the-range model.

Finally, there was time for a family picture. From left to right: Daryl Wilson, Sheryl Wilson plus Natalie and Mansour Mamaghani of German Wilson Audio distributor Audio Reference.

Finally, there was time for a family picture. From left to right: Daryl Wilson, Sheryl Wilson plus Natalie and Mansour Mamaghani of German Wilson Audio distributor Audio Reference.

The next morning, the journey continued to our next stop. But what we experienced at Dan D'Agostino is a story of its own...

All images courtesy of Carsten Barnbeck.

0 comments