A customer recently imported a vintage Presto 75A disk recording lathe from the US, with a view to cutting records in Europe. [J.I. is based in Europe – Ed.]

He quickly discovered, like many people before him, that it was spinning a bit slower than it should, when operated from European 50 Hz AC via a simple step-down transformer. As with most vintage record cutting machines, the platter is powered by a synchronous AC motor, which “locks” to the line frequency.

The Problem with Industrial Inverters

He then tried to run it from an industrial inverter, a device similar to a phase inverter and intended for controlling the speed of industrial motors. The first issue with this is that such industrial applications do not normally require highly accurate speed control. The second problem is that inverters and VFDs (variable-frequency drives) are usually paired with motors designed to be powered by such devices – which don’t include cutting lathes! Their output is quite far from a pure sine wave and contains a lot of harmonics, extending to high frequencies. This tends to produce an audible whine from older motors and causes them to overheat, greatly reducing their performance and reliability.

When we tried to run the Presto from the inverter, the high frequency whine was even finding its way to the cutter head as electro-magnetic interference (EMI).

The inverter was promptly discarded and a new capstan was machined, to allow the motor to run from 50 Hz and still transmit the correct speed to the platter.

This process was described in more detail in this link. It was tricky, but we successfully converted the machine to run at an accurate 33 1/3 and 45 (instead of 78) rpm, connected directly to our EU mains.

A step-down transformer, a special version of our Type 1760, was designed and installed inside the lathe, to deliver the appropriate voltage to the motor for quiet and reliable operation without overheating.

Renewing the Wiring

There was a plate on the side of the lathe, that housed audio connectors. These were wired to a different standard than what is presently used by the audio industry. Some wires were cut, others were missing the insulation, and the wiring inside the machine had been badly bodged. It was a mess, even posing a safety hazard to the operator and equipment. The power cord was loosely coming out from a hole in the chassis, with the ground connection loose. We decided to remove everything and start from scratch.

We made a new plate to replace the old one. The new plate would accept an IEC power connector and mains fuse. There was no fuse anywhere on that machine when we got it! Since the metallic plate is only attached to the wooden frame, it also had to be reliably grounded. Similarly, all metallic parts of the machine were grounded.

On the other side of the machine, there was an ugly, butchered plate with electrical tape over it. Upon removing it and turning it around, it was discovered that this was a knob dial, pressed into service, from a machine manufactured by Cinema Engineering Co., of Burbank, CA. They used to also make disk recording equipment, but they are very rarely seen nowadays.

Next to it was a badly drilled hole with nothing in it. We enlarged the hole by civilized means, resulting in a properly round and smooth mounting hole for a fuse holder. A stainless steel round plate was made, with the Agnew Analog logo engraved in it, to hold a ¼-inch jack connector for hooking up the cutting amp.

The Mechanical Assembly: Inside-Out and Outside-In

With the wiring sorted, it was time to work on the mechanical assembly. This machine is very simple and elegant in this respect. A lever on the side allows the operator to shift between Inside-Out, Neutral and Outside-In cutting modes. This engages the cutting arm (or disengages it in Neutral) and defines the direction of the cut. Records can therefore just as easily be cut from the outer edge towards the center, or from the center towards the edge. Inside-out records were commonly used in the broadcasting sector. The practical significance was that if a recording was too long to fit on one disk, the sound would gradually change from the outer diameter to the inner diameter of the disk, and the sonic transition from the end of the first disk to the beginning of the next would be too abrupt. By recording the first disk outside-in and the second one inside-out, the abrupt sonic transition was eliminated.

The platter shaft has a worm gear at the top which engages the central geared portion of a horizontal shaft:

A bronze rack is attached to the cutting arm, while the horizontal shaft and its base are attached to the Direction-of-Cut lever. In Neutral, there is no contact between the horizontal shaft and the rack:

A bronze rack is attached to the cutting arm, while the horizontal shaft and its base are attached to the Direction-of-Cut lever. In Neutral, there is no contact between the horizontal shaft and the rack:  When the lever is moved to the "Outside-In" position, one of the worm gears at one end of the horizontal shaft meshes with the rack teeth and advances the cutting arm inwards:

When the lever is moved to the "Outside-In" position, one of the worm gears at one end of the horizontal shaft meshes with the rack teeth and advances the cutting arm inwards:

When the operator shifts the lever to the "Inside-Out" position the other worm gear meshes, advancing the cutting arm outwards:

The central portion of the horizontal shaft remains permanently meshed with the worm gear on the platter (vertical) shaft. The rack ends shortly before the inner and outer limits of the cutting arm travel, disengaging from the worm gear, to prevent "crashes." Two end-stops limit the travel of the cutting arm so it does not collide with something expensive, if manually pushed all the way to the end.

Fixed-Pitch and Double-Groove Records

With this design, the machine is limited to fixed-pitch operation, at 96 LPI (lines per inch) However, due to its intelligent design, the pitch is highly accurate. There are no grouping effects whatsoever. As it is also a rather coarse pitch, it leaves plenty of room to cut double-groove records, where a different song plays each time you put the needle down on the record depending on where it happens to land!

One would really have to try hard to break this machine. With proper maintenance it works like a horse!

As with all precision instruments, the 75A requires careful adjustment to run well. The horizontal shaft was sorely out of adjustment, causing noise. Someone had filled up the main bearing with grease…! Please, never use grease on precision mechanical instruments, unless the manufacturer explicitly calls for it. It may work fine for crude and primitive tools for the farm, but it has no place in precision lathe bearings, which are usually designed for a particular type of light machine oil.

The presence of the correct oil in the assembly is as important as any of the solid parts! Consider the oil as part of the assembly. The lathe won’t run as intended without it!

In the absence of the original specifications, the type of oil can be calculated by measuring and calculating the clearances, load, speed, temperature, friction, materials, accuracy required, and several more factors. This is best left to a qualified mechanical engineer with experience in machine tool design, but also well versed in the particular application of disk recording.

Fortunately, the manual for this lathe specifies the lubrication procedures, so we do not need to reinvent the wheel. We can supply all the lubricants specified, if required.

The Interesting Little Details

The Presto badge is particularly noteworthy on this machine, resembling a record.

The Presto badge is particularly noteworthy on this machine, resembling a record.  Also noteworthy is the fact that this machine has matching serial numbers on all parts, proving all parts to be original, as fitted by the factory:

Also noteworthy is the fact that this machine has matching serial numbers on all parts, proving all parts to be original, as fitted by the factory:

Many disk recording lathes have an oil dashpot for damping the suspension. Others have an advance ball system, a mechanical means of controlling and regulating groove depth, while others have nothing at all.

The 75A, being marketed as a portable machine, came with a “dry” dashpot:

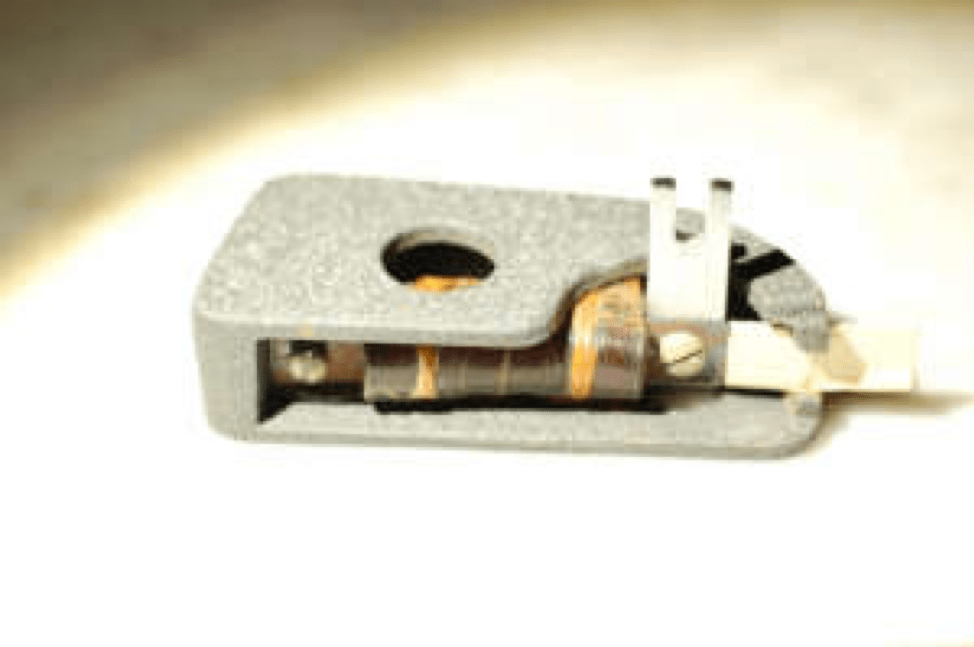

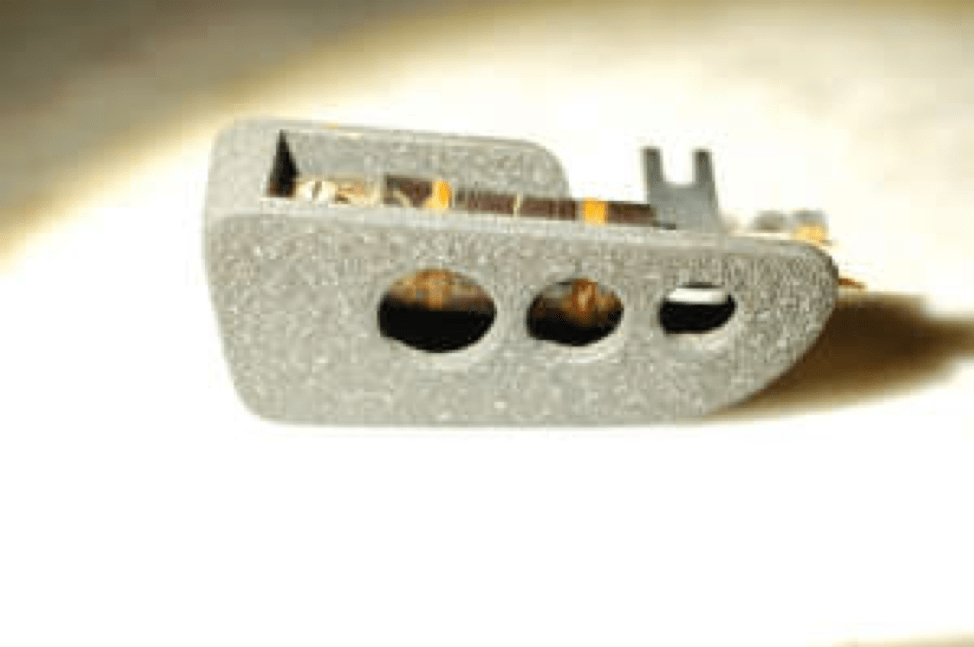

This is the Presto 171-A damper, especially suitable for portable systems, as there is no oil or other liquid to spill and make a mess!

This is the Presto 171-A damper, especially suitable for portable systems, as there is no oil or other liquid to spill and make a mess!

It is a very heavy brass casting, suspended on a reed spring, damped heavily, and tuned to counteract the vertical oscillation tendencies when cutting lacquer disks with a Presto cutter head.

Don’t laugh, it actually works!

This machine was in need of a cutter head, so we paired it up with an RCA MI-4889, a moving iron design, also dating from the 1930's.

This machine was in need of a cutter head, so we paired it up with an RCA MI-4889, a moving iron design, also dating from the 1930's.

These heads are quite sturdy and can sound good if used with due care.

A friend of the owner got excited about all this and built a custom cutting amp with built-in RIAA pre-emphasis:

As a final touch, we made a custom mount for a microscope stand to fit the chassis. A very basic groove and stylus inspection microscope is thus provided, which is essential for adjusting cutting parameters, troubleshooting and inspecting the final product.

As a final touch, we made a custom mount for a microscope stand to fit the chassis. A very basic groove and stylus inspection microscope is thus provided, which is essential for adjusting cutting parameters, troubleshooting and inspecting the final product.

The result is a fully restored, fully functional disk recording lathe that will take any blank size from CDs to 16-inch blanks and will cut or emboss. CDs are the cheapest, easiest and most widely available material that grooves can be cut/embossed onto with acceptable fidelity and have found widespread use among users of vintage disk recording lathes. In some cases, the same CD can then be played back both in a CD player and on a turntable!

The performance is very good for its age and it can even cut master lacquer disks, within its operational limitations. It is portable, reliable and easy to set up, making it the ideal system for mobile recording and events.

This machine was deemed to fulfill the notoriously high performance expectations of the British Broadcasting Corporation and was widely used in various BBC studios. It was commonly installed in sturdy, floor-standing cabinets. Two of these can be seen side by side in an installation in Aldenham, in a photograph dating from 1949, on Plate 6, between pages 106 and 107 of the BBC Recording Training Manual, published by the BBC in 1950. A close-up of the speed selection lever appears as Fig. 97 on page 108.

This article was originally published on the Agnew Analog Reference Instruments website, www.agnewanalog.com.

0 comments