Over the past few years, we have restored a number of SME 3009 and 3012 tonearms, covering most of their variants made over the impressively long production life span of this model range.

This outstanding tonearm was first introduced in 1959, setting a standard for high performance tonearm design which is still hard to beat, 60 years later.

We have used our restored SME tonearms on a large number of reference reproduction systems, for our own use and for our customers, such as the Thorens TD160 project which was presented here last February. These systems are excellent for Quality Control in vinyl record manufacturing, to ensure that any defects are caught early.

They are of course also capable of offering an intensely enjoyable, accurate listening experience, coupled with an accurate cartridge.

This array of parts is an SME 3012, the bigger version of the 3009, from the period of Shure's involvement with SME. It was found on a Neumann disk mastering lathe, a common application for the 3012, its length allowing it to reproduce disks from the massive 16" vacuum platter. The new owner of the Neumann lathe did not want to keep the tonearm, which was admittedly in a very poor state of neglect. As such, it was removed, carefully cleaned and disassembled for the repair and restoration to begin.

The most interesting features on this version of the 3012 are the leadscrew system for advancing the counterweight, along with the method of decoupling the counterweight assembly and adjusting lateral balance.

This system was completely jammed, but with our precision machine tools in our R&D laboratory, it was easy to machine the required replacement parts, in house. It now operates smoothly and is a real pleasure to adjust.

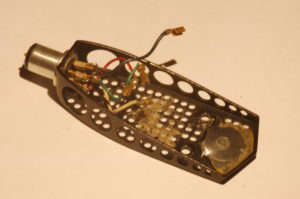

This version came with the sliding screening can and 4-pins-in-series connector at the bottom, shown at the left.

An alternative arrangement is the screening can on the right, with a pair of RCA connectors. Our personal preference is no connector at all, with the tonearm wiring soldered directly to the interconnects, or even better, a continuous run of wire all the way to the preamplifier. In fact, on the 3009 versions with non-removable headshell, it is possible and preferable to run twisted pairs, suitably screened, from the cartridge pins to the preamp, with no connectors or soldering in between. Even better, soldered directly to the sockets of the Western Electric 437A tubes in the balanced Agnew Analog Reference Instruments Type 751 reference phonograph preamplifier, keeping wiring accurately balanced throughout.

The SME 3012 features a removable headshell. This contributes to a higher effective tonearm mass, due to the location of the connector being close to the tip. The 3012, being a 12" arm, is obviously not designed with the lowest possible effective mass as an objective, but was instead offering the comfort of a removable headshell demanded by professional users. In any case, the "tin foil hat" tweak seen here is a very bad idea! Please do not do this to your poor tonearm! It works great as it is, if you are using a decent cartridge and do the wiring properly.

Removing the foil, we are left with a mess of glue to clean up, to restore this classic to proper standard.

This is how it should look. Well, almost. We still need to install some proper wires and connectors there. But we shall defer this to the end of the restoration process.

While on the subject of headshells, SME made their version "rigid": The mounting faces are metallic, as seen on the SME headshell on the left. The headshell on the right uses a rubber ring gasket as the mounting face. This is easier/cheaper to manufacture, but the performance is worse, as it allows more flexing and a sloppier registration of location.

The SME headshell mounting system (left and right) is generally not the most accurate way to mount a removable headshell. Better geometric accuracy and repeatability over multiple mounting cycles can be achieved with a cone-type mount, as can be seen on the headshell in the middle, from a Thorens TP16 tonearm. However, this is more difficult to manufacture accurately and if badly executed, it would be worse than a flat-face mount.

The anti-skating arrangement on the SME 3012 and 3009 tonearms is a weight on a string. Gravity acts on the weight, which pulls on the string, going through a guide and attached to a lever at the back of the tonearm. The notches on the lever allow anti-skating force adjustment for different values of vertical tracking force.

The original guide, shown on the top, was just a suitably bent wire. Friction at the point of contact was high, so this was later re-engineered with a pulley on the top.

This was a significant improvement, and while it could possibly get even better with jewelled bearings, the cost would be much higher.

The story of the evolution of the SME 3009 and 3012 tonearms reveals, once again, that the limit to what can reasonably be achieved, is more often than not economically imposed rather than technologically imposed.

Header image courtesy of Wikimedia Commons/Jacques. All other images courtesy of Agnew Analog Reference Instruments.

This article originally appeared on the Agnew Analog Reference Instruments blog and is used by permission.

0 comments