A few days ago I was in the lab (which in itself is hardly surprising, considering that a significant part of my life is spent there) winding some tiny coils for some experimental transducers, when it suddenly dawned on me that what seems like a remarkably simple idea (winding some wire into a coil) is actually the very basis of recorded and reproduced sound throughout the entire electric era, from the 1930s to the present day.

Winding a coil in the lab. Photo courtesy of Agnew Analog Reference Instruments.

Most of you are probably well aware that audio transducers (devices that convert from one form of energy to another) such as loudspeakers and microphones are often using coils. These are in effect miniature motors, moving the diaphragm (cone or other) in headphones and loudspeakers, or generators, generating an electrical signal in microphones.

In addition, moving coil, moving magnet and moving iron phono cartridges also contain coils and function as generators. Not only that, but to create the records that phono cartridges reproduce, cutter heads containing coils are employed, acting as motors that move the cutting stylus. Turntable and disk recording lathe motors are also based on coils of wire.

A Neumann cutter head and an empty custom machined coil former, shortly before winding the wire on it. Photo courtesy of Agnew Analog Reference Instruments.

With the exception of a few very experimental devices, tape recording and playback heads employ coils, not to mention the multiple motors and solenoids to be found on tape machines.

Then we have the less obvious uses of coils in electronics. The most basic form of resistor is the wirewound resistor, wound as a coil of resistor wire, either nichrome or one of the more exotic alloys such Manganin and Constantan.

Many types of capacitors are also formed by winding foils of different materials into coils.

Then we have inductors, which are essentially just coils, air-coiled or iron-coiled!

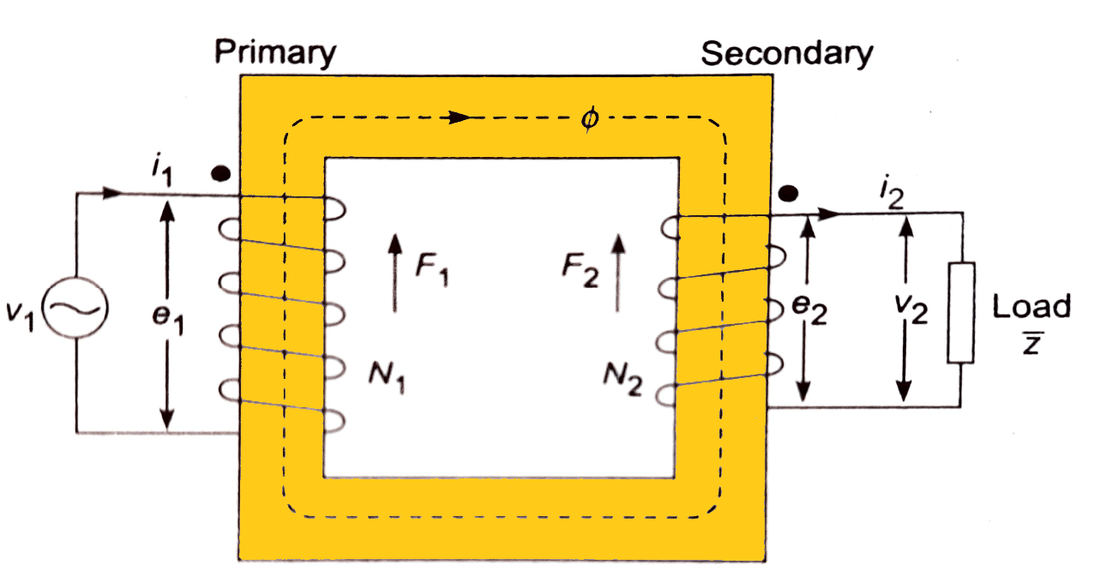

If two or more coils are magnetically coupled together, a transformer is created, usually built around an iron core for audio frequency work. These are often used to step up the small signals produced by moving coil phono cartridges and microphones or in the output stages of vacuum tube amplifiers.

While on the subject of vacuum tubes, their grids are also wound as coils of wire and the heaters of indirectly heated tubes are often helically wound, all within the glass envelope of the tube.

Transformers are also universally used in the power supplies of all audio equipment.

Custom Agnew Analog transformers. Photo courtesy of Agnew Analog Reference Instruments.

Not only that, but electrical power generation also largely depends on coils! Whether we look at diesel, coal, nuclear, gas, hydroelectric, or wind power generation systems, the generator always contains windings. Power distribution heavily relies on coils for the transformers used throughout the power grid. Even the alternator in your car, which generates the power needed to charge the car battery, operate the ignition system (on gasoline engines) and power the radio, cassette player, cartridge machine or car turntable (yes, they once existed!), relies on windings!

The pickups used on electric guitars, basses, many electric pianos and electric organs are elaborately-wound coils. Guitar amplifiers often use tubes, transformers and inductors. Mixing consoles as well. Same with the circuits used in electronic synthesizers and the analog signal processing electronics found in abundance in recording studios.

Radio transmitters and receivers typically contain radio frequency inductors, which are also just coils.

In fact, one can put together an entire sound recording studio and reproducing setup consisting solely of coils of different geometry and wire/foil materials and it wouldn’t even be very unusual. Granted, for certain applications, it has been deemed preferable in recent decades (mainly from an economic standpoint) to move away from the coil form for things like resistors and capacitors, but the wound types are still widely available and still needed for certain applications.

One of the coils on a rebuilt Presto cutter head. Photo courtesy of Agnew Analog Reference Instruments.

For something as simple as winding some wire into a coil, the complexity of some coil winding geometries, wire materials sizes, shapes, coil former types and the diversity of winding equipment in use is just mindblowing.

The applications, in audio alone, for coils of wire, are innumerable. Even the tip of the cutting stylus in a disk mastering system has a miniature coil wound around it to provide stylus heating, which helps achieve a lower noise floor on disk.

Loudspeaker crossover networks? You guessed it, coils there too! Ribbon tweeters? They need transformers, so they tend to have coils as well, not to mention that the ribbon itself can be seen as a single-turn coil!

The applications mentioned herein include but are not limited to the pioneering work of Michael Faraday, Joseph Henry (electromagnetic induction), Ottó Bláthy and Miksa Déri, Károly Zipernowsky, George Westinghouse, Albert Schmid, Oliver Shallenberger, Lucien Gaulard, Sebastian Ferranti, and William Stanley (transformer development), Lee de Forest (triode tube), Otis Boykin (resistor), Edward W. Kellogg and Chester W. Rice (cone loudspeaker), Ernst W. Siemens (moving-coil transducer), André-Marie Ampère (electric solenoid), Thomas Davenport and Emily Davenport (electric motor), Emile Berliner and Thomas Edison (phonograph, gramophone, sound recording and the microphone).

Audio-Technica AT-ART9XI phono cartridge. Photo courtesy of Audio-Technica U.S., Inc.

The list of people who contributed to the vast collection of ideas on what to do with a piece of wire is far too long to even attempt compiling a complete version in the short space of this article.

The coil, in all its forms, is indeed the heart of the electrical era of audio. Given enough wire of the correct sizes and material, all the essential audio components could be built from scratch. Well, OK, we’d still need the mechanical parts such as coil formers, loudspeaker cones and at least a turntable, but you get the idea!

Header image courtesy of Wikimedia Commons/Electrical Classroom.