Presto 1-D and 1-C cutter heads are frequently encountered on our lab bench for repair and restoration. Some are just regular repairs to bring them back to original spec, others are rewound to operate at a different impedance, but some undergo more comprehensive and exciting modifications!

We have previously examined modifications where a feedback system was added to a Neumann MS-52H and an Audax R-56 cutter head. This time, we shall discuss adding feedback to a Presto 1-D, which arrived with damaged coils.

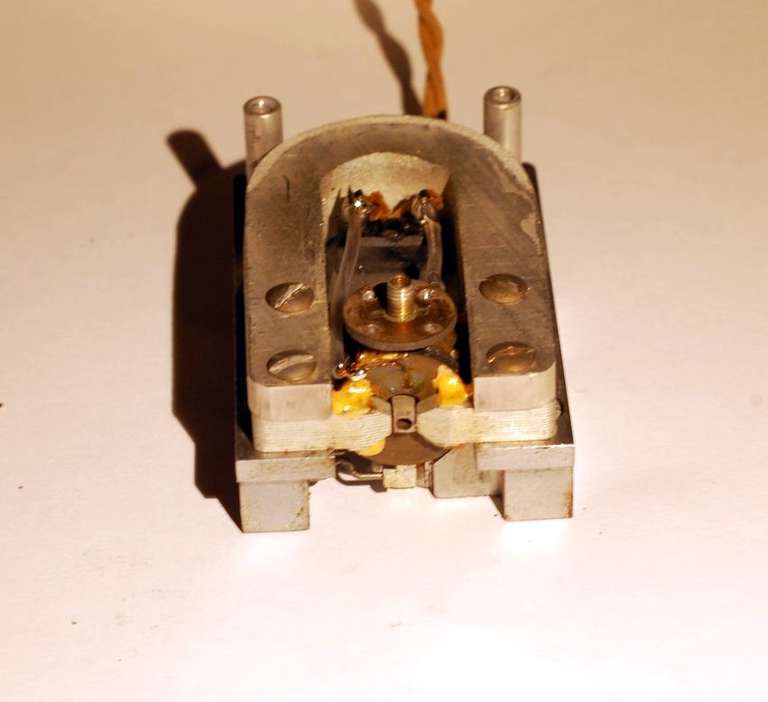

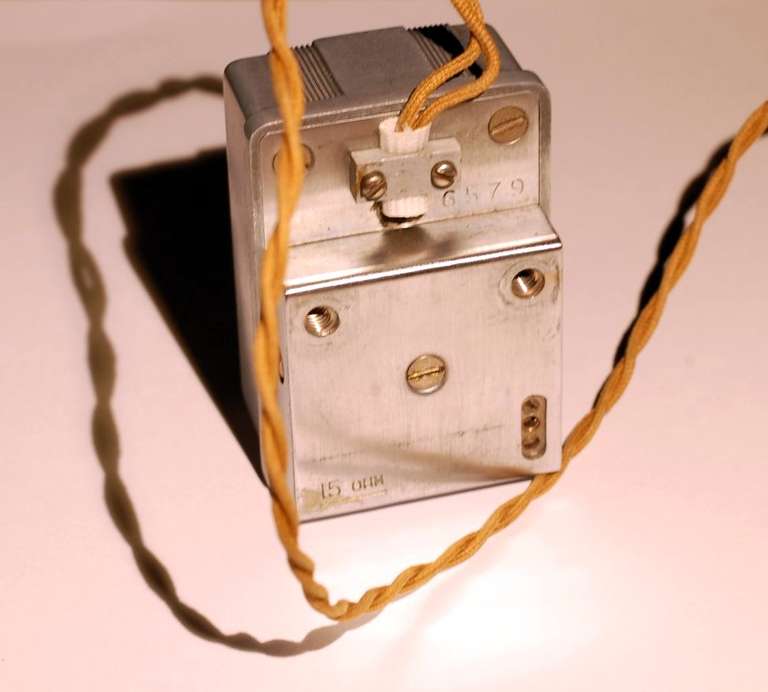

The Presto 1-D consists of a horseshoe magnet, laminated pole pieces, two drive coils, an armature pivoted on a knife-edge bearing, a set of springs, and a large damper.

The iron armature is quite large and heavy, which is the biggest limiting factor in the performance of the Presto 1-C and 1-D, both of which use the same armature design.

The first step was to machine new coil formers, to accept the new coil assembly that uses feedback as a means of accomplishing more accurate disk cutting.

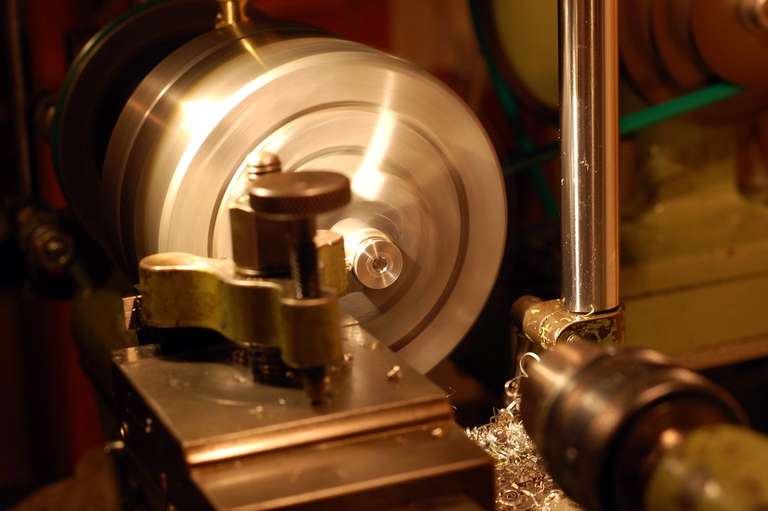

This took some delicate machining on our 1930s Lorch precision optical lathe, as the wall thickness of the formers is only a small fraction of a millimeter! Thin-wall micromachining has been the subject of several research projects in the fields of mechanical engineering and industrial manufacturing processes for several decades now, due to the challenges it presents. Features with a wall thickness under 1 mm and a height-to-thickness ratio larger than 5 are generally considered particularly difficult to machine. In these coil formers, the height to thickness ratio is around 30, while tight geometric and dimensional tolerances had to be maintained!

The machined formers were then taken to our precision milling machine to drill the tiny holes for the wires to enter and exit the former.

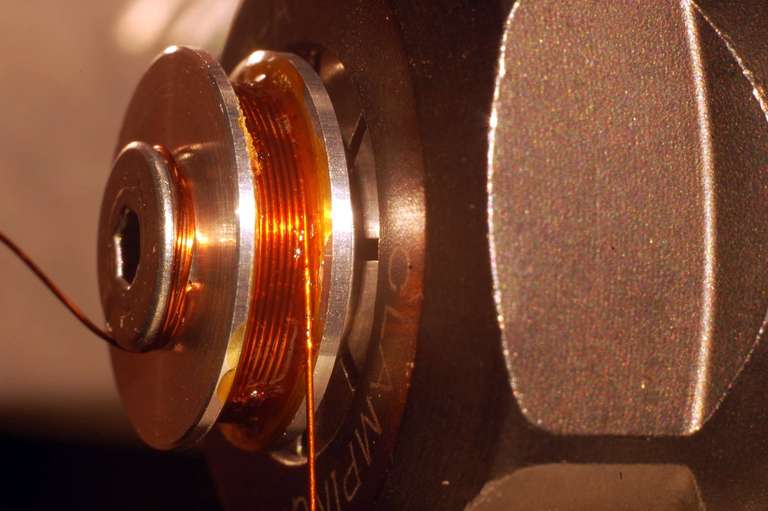

After cleaning and inspecting, a pair of tiny coil formers were selected and brought to our coil-winding machine for the winding operations.

The completed coils were then varnished for stability and assembled into position.

The armature needed to be properly adjusted, and various performance tests could then be conducted to verify that the transducer operated as initially mathematically calculated, under the new feedback configuration.

This modified version shall now be called the Presto 1-DA. It is currently in active service at Epos Laboratories (https://www.instagram.com/eposlab/) in Greece.

Further information, measurements and a mathematical analysis will appear as part of a research paper, to be published in due course.

Many of these feedback techniques originate from the research and development efforts at Agnew Analog Reference Instruments over the past couple of years, towards the design of a new stereophonic cutter head.

This article originally appeared on the Agnew Analog Reference Instruments blog and is used by permission.

All images courtesy of Agnew Analog Reference Instruments.

0 comments