[Ken Fritz has abilities and ambition that put most of us to shame. Ken decided to build his own speakers—and the listening room for them. As you’ll see, he did everything in a big way. Having produced tooling for the cast polymer baffle for the Thiel CS5, Ken says, ” I thought I’d cast baffles for this system also.” As one would. ;->

The scope of the work required to build both speakers and room will take at least two articles to convey—maybe three. Meanwhile: take a look, and be amazed. —-Ed.]

Building loudspeakers has always been a hobby. Back in my high school days, 1956 and on, I built a pair of ElectroVoice Patricians which I used for 25 years—and I still have all the drivers. After hearing an Infinity Quantum Line Source at Stereo Exchange, I realized Line Arrays were the way to go. Since then, I’ve built three iterations of line sources until I finally decided upon the system I now have.

Before embarking on the project, I spoke at a CES show with Igor Levitsky, who did design work for Bohlender Graebener. I asked him if I was making a mistake in design, and was relieved when he told me I was on the right track, and furthermore, suggested the crossover points for the BG RD50 drivers I chose to use. I also asked for a personal meeting with speaker designers Joe D’Appolito and Vance Dickason, together. I was concerned that my choice of drivers wouldn’t integrate properly; luckily, both were more than familiar with my choices and told me I couldn’t have made better ones. They did tell me, however, that I’d need to sit at least 16 feet from the speakers so that the cylindrical waveforms would integrate properly. In the finished room, the listening position is 26 feet from the speakers.

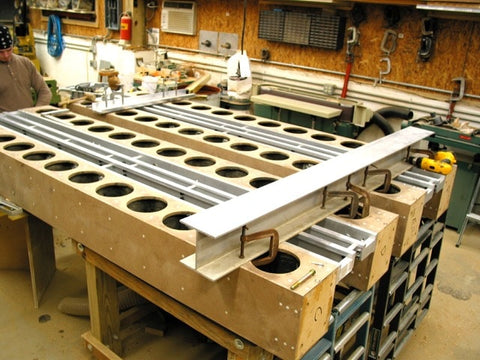

I used 16 15-inch metal cone drivers, sourced from Krell, from 60Hz on down. They were built for me by Thilo Stompler, who suggested using a surround with an Xmax of 2 inches rather than the 3 1/4-inch surrounds they used for Krell. Dan D’Agostino was gracious enough to allow me to purchase them directly from TC Sounds. I also used: 24 7-inch ScanSpeak kevlar cone mid-bass drivers per channel, going from 60Hz to 200Hz; four BG RD50 drivers from 200Hz up to 6500Hz; 40 Panasonic EAS-10TH 400A leaf tweeters from 6500Hz up, 30 tweeters to the front and 10 to the rear, out of phase from the front, for a dipolar pattern.

The surround speakers use six 8-inch ScanSpeak Revelator bass drivers up to 500Hz, six 3 1/2-inch ScanSpeak Revelator mids up to 3500Hz, and six ScanSpeak Revelator dome tweeters from 3500Hz on up.

The electronics are from Krell: five KBX active crossovers, three FPB 600s, four FPB 300s, and one EVO 403. I’m using four Crest Audio 6500 watt stereo amps to drive the 16 bass drivers, as they require that amount of power to perform properly.

Before finishing the room, I had Acoustics First, a Richmond company that specializes in room design for commercial projects, come out and do ETF measurements of the room. They then had Owens Corning manufacture 4ft x 5ft sound panels, according to their patented algorithm, that I integrated throughout the walls in the room.

I must say that the help and suggestions I got from well-known industry experts were instrumental in the success of my project.

[In the next issue of Copper, we’ll go more into the fine points of Ken’s amazing speaker project—Ed.]