We’ve looked at a variety of methods of making music—or at least generating a signal— from a record groove. We’ve seen phono cartridges that use coils and magnets, all kinds of armatures, and even condensers/capacitors.

What’s left?

There are still a number of methods left to be looked at, but in this brief installment, we’ll look at strain gauges. What are they? And what are the advantages of cartridges that utilize them as the generating system? To quote Omega, a prominent maker of such things, a strain gauge is “a sensor whose resistance varies with applied force; It converts force, pressure, tension, weight, etc., into a change in electrical resistance which can then be measured.”

Strain gauges are used to measure deflection of airplane wings and other critical structural elements. Strain gauge-based phono cartridges are displacement-sensing rather than velocity-sensing (like most magnetic cartridges), and thus don’t require RIAA compensation. The advantages of strain gauge cartridges are eloquently described by Peter Ledermann of Soundsmith, maker of the only strain gauge cartridge in current production.

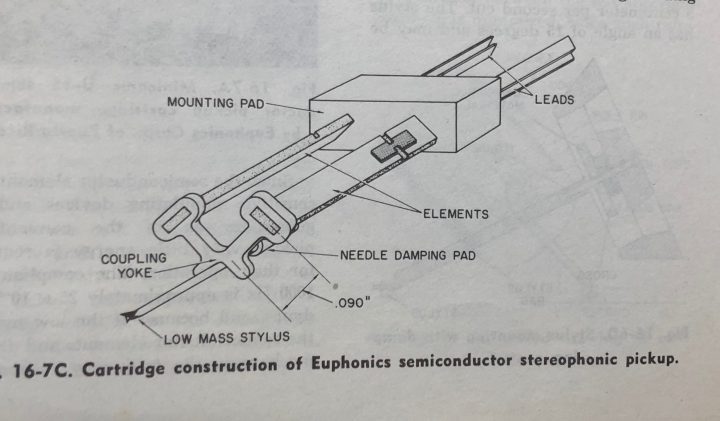

The first use of strain gauges as the generating elements in phono cartridges was, to the best of my knowledge, by a company called Euphonics, based in Puerto Rico in the early 1960s. Euphonics also manufactured inexpensive ceramic phono cartridges, and from all I can find, the Euphonics Miniconic system consisted of tonearm, cartridge, and power supply for the cart.

The Euphonics Miniconic system.

The generating system of the Euphonics cartridge is shown in this drawing (published in the venerable Audio Cyclopedia); to my knowledge, subsequent strain gauge cartridges have been constructed along similar lines.

The highest-production strain gauge cartridges were those of the EPC series, made by Panasonic in the early to mid-1970s. Some models were designed for Quadraphonic (four channel) playback, and required an external demodulator. Some models utilized a Shibata stylus, and were known to be excellent trackers.

The interesting thing about the Panasonic cartridges is not the cartridges by themselves, but the fact that their potential performance was limited by their associated electronics. Over the years, several gifted designers have come up with power supplies and EQ systems that have transformed the Panasonic carts to world-class. The cartridges are still available on the secondary market, and many hobbyists have tried their hands at improving their performance with homebrew electronics—as seen here and here.

So what “gifted designers” have worked with the Panasonic strain gauge cartridges? First and foremost was John Iverson, whose Electro Research and Electron Kinetics companies produced extraordinary companents that are still sought-after today—and in fact, some are still made in modified form by former associates. An interesting sidebar to Iverson’s story is that he disappeared—poof!— and that has created a whole rabbit’s hole of theories as to the how and why. (Sidebar to the sidebar: don’t confuse him with longtime Stereophile reviewer, Jon Iverson. Poor Jon has heard it all….)

In the early ’80s Electro Research made a tank-like power supply/pre for the Panasonic strain gauge cart; the EK-1 had a chassis made of 1/4″ stainless steel, and cost $4000, with the cart. $4000 in 1982. Think about that. The unit was made in Singapore; Iverson once claimed that the EK-1 would’ve cost $20,000 if made in the US.

The Electro Research EK-1.

These days the Panasonic strain gauges are the basis of a system designed by the versatile audio craftsmen Dave Slagle and Jeffrey Jackson, whose partnership is known as Emia. Dave and Jeffrey combine old school handwork and technology (mercury vapor rectifiers. anyone??) with some interesting modern twists. What they make utilizing the Panasonic cartridge is pretty extraordinary., as you can see here.

Back in the mid-’70s, a purpose-built strain gauge cartridge was made by Win Labs. Dr. Sao Win still appears every now and then in the audio world, and apparently still takes care of his SDT-10 strain gauge carts and later models (including a FET-based cartridge). The cartridge was known to have a rather penetrating high end, sometimes alleviated by use of tube-based power supplies, such as the one made by San Diego dealer Audio Dimensions. Win also made stunning and expensive tonearms and turntables, still sought by collectors.

While Emia and others still work with the Panasonic strain gauge cartridges, the only scratch-built strain gauge cartridge systems made these days come from the aforementioned Soundsmith. I’ve heard the Soundsmith strain gauge many times, and its effortless quality is the closest thing I’ve heard to reel-to-reel. I’ll get a system one of these days….

While Emia and others still work with the Panasonic strain gauge cartridges, the only scratch-built strain gauge cartridge systems made these days come from the aforementioned Soundsmith. I’ve heard the Soundsmith strain gauge many times, and its effortless quality is the closest thing I’ve heard to reel-to-reel. I’ll get a system one of these days….

0 comments