In Issue 125, J.I. covered the mechanical aspects of record cutting with respect to stylus rake angle (SRA) and vertical tracking angle (VTA). The series concludes with a further examination of the mechanics of record cutting and playback.

The reproducing stylus and the phono cartridge it is attached to, together form an instrument which traces the groove on a record, aiming to replicate the mechanical motion of the cutting stylus at the time the record was cut and in turn, generate electrical signals. In an ideal world, after the signals go through the phono stage, they would be identical to the electrical signals generated by the microphones and associated electronics at the time of recording.

There are several factors conspiring against this nirvana, at the groove-stylus interface. The reproducing stylus cannot have a rake angle per se, as it is not a cutting tool. What the stylus rake angle actually refers to, when it comes to the playback side of things, is a form of vertical fore-aft azimuth. In other words, it is a scanning angle. This angle must be in agreement with the rake angle of the cutting tool to enable the playback stylus to follow the original path of the cutting stylus, as accurately as permitted by a multitude of other factors. The accurate extraction of information greatly depends on this.

Ruby cutting stylus held in special tool for installation. Image courtesy of Agnew Analog Reference Instruments.

Ruby cutting stylus held in special tool for installation. Image courtesy of Agnew Analog Reference Instruments.At the same time, the accurate extraction of information also depends on reading along the same plane of modulation as the information contained within the groove. This is no longer about machining and mechanical engineering (but is still also about cutting a record).

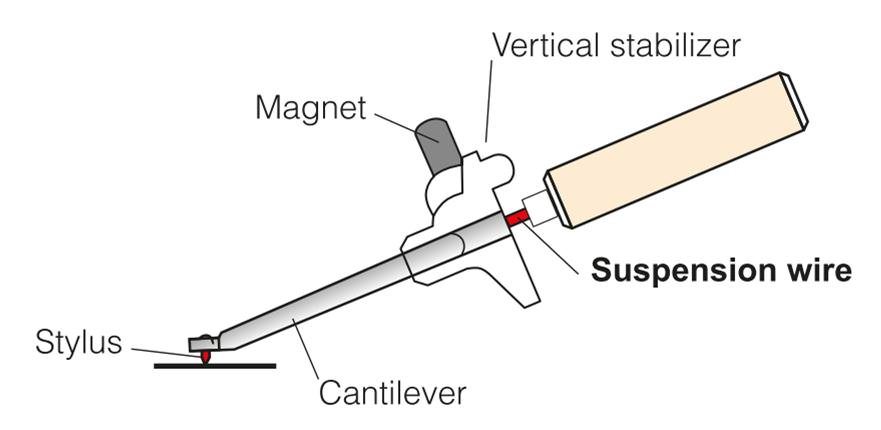

In the case of pretty much all modern phono cartridges, the playback stylus is located at one end of a cantilever, the other end of which is suspended and acts as the pivot point. Therefore the stylus will always scribe an arc when moving in any direction. This means that the playback stylus will necessarily read at an angle in the vertical plane, depending on the length of the cantilever and its configuration where it meets the generating system. With the phono cartridge body exactly parallel to the record surface, the stylus rake angle, in contrast, only depends on the orientation of the playback stylus itself, which could be 0 degrees or any other value the designer of the cartridge decides upon.

If we were to tilt the entire phono cartridge up or down from being exactly parallel to the record surface, we would be tilting the playback stylus with it, thereby changing the SRA, but we would also be tilting the cantilever and generating system, which would change the vertical tracking angle. Both the VTA and SRA must match the equivalent parameters used by the cutter head to cut the record, in order to yield accurate reproduction. But, the relationship between VTA and SRA is not the same for all phono cartridges, nor is it the same for all cutter heads. This is a very important point. To stand any chance of accurately extracting information, a phono cartridge must have its SRA/VTA relationship designed in to match a particular cutter head!

Phono cartridges must, therefore, be designed by people possessing intimate knowledge of cutter head design and use in the field. This is rarely the case nowadays and even then, any given phono cartridge can only ever achieve accurate reproduction of records cut with the particular cutter head it was designed after! It will of course play all records and it may even sound reasonably pleasant, but it will not be accurate unless the cutter head SRA/VTA relationship is compatible.

Closeup of a Shure V15-III-XM phono cartridge. Image courtesy of Agnew Analog Reference Instruments.

Closeup of a Shure V15-III-XM phono cartridge. Image courtesy of Agnew Analog Reference Instruments.This is a main reason why some cartridges will play some records better than others.

This also implies that if a phono cartridge is designed with a random SRA/VTA relationship that does not match any cutter head in actual use, then this cartridge will be practically useless if truly accurate reproduction is the goal. Furthermore, it shows that there is no one-size-fits-all cartridge that can accurately reproduce all records. If a wide variety of records, cut using different cutter heads, is to be reproduced, more than one cartridge will be needed if accuracy is the goal. Then again, there is the philosophical question of, how much accuracy do we really want? This was discussed in “How Hi Would You Like Your Fi?” in Issue 121.

Just as playback SRA is a bit of a misnomer, as previously discussed, the concept of vertical tracking angle during the “recording” (record cutting) process is also something that does not makes sense, since a cutter head does not track, it cuts and modulates. As such, the equivalent of playback VTA on the recording side is the vertical modulation angle, or VMA. The concept is similar to playback VTA, but VMA defines the angle at which information is recorded on the vertical plane, to be subsequently reproduced by a phono cartridge tracking at that same angle in the vertical plane.

In many cutter heads, the cutting stylus is located at one end of a cantilever (called a torque tube), the other end of which is suspended, forming a pivot point and forcing the cutting stylus to move in an arc. Neumann and Westrex cutter heads used this configuration, but with very different parameters. Ortofon cutter heads, on the other hand, used the rocking bridge system, where the cutting stylus would be pushed up and down in a straight line, but the entire head would be tilted to give the desired VMA. For any given cutter head’s vertical modulation angle, the SRA can be any value, depending on the orientation of the cutting stylus, which, along with the VMA, is designed in.

Caruso cutter head torque tube with cutting stylus installed. Image courtesy of Agnew Analog Reference Instruments.

Caruso cutter head torque tube with cutting stylus installed. Image courtesy of Agnew Analog Reference Instruments.Just as every phono cartridge has a specific SRA/VTA relationship designed in, every cutter head is also designed for a specific SRA/VMA relationship. If we take a cutter head and a phono cartridge with a compatible SRA/VTA relationship, and tilt the cutter head on the lathe to increase both the SRA and the VMA, then the phono cartridge would also need to be tilted upon playback, to not only maintain the correct SRA/VTA relationship, but also to maintain the correct absolute values of SRA and VTA.

But, while most lathes do offer some means of adjustment of cutter head tilt, most playback tonearms do not. A popular misconception is that the tonearm height adjustment is a “VTA adjustment,” which it is not. Most tonearms are designed to operate parallel to the record surface. The range of height adjustment is usually quite limited and will not drastically tilt the cartridge. What it will do, if adjusted to anything other than parallel to the record surface, is alter the dynamic motional behavior of the tonearm and most probably, compromise its performance. The only realistic means of phono cartridge SRA/VTA adjustment would be a tiltable headshell or cartridge mount, allowing the tonearm to remain horizontal while permitting the cartridge to be tilted as required. These do exist and I have even made some custom ones in the lab to experiment with (to be discussed further in a future piece). But for most off-the-shelf playback systems, the cartridge cannot be tilted, so the designed-in SRA/VTA relationship and absolute values must be as required for the records we are aiming to accurately reproduce.

Finally, it must be borne in mind that manufacturing tolerances will inevitably bring some variation from the published SRA/VTA values (if these exist at all) from sample to sample of the same make and model of phono cartridge. These values will also almost certainly change a bit when replacing the stylus assembly on MM cartridges or when re-tipping.

Sapphire cutting stylus installed in Agnew Analog Type 1501 long shank adapter for use in vintage monophonic cutter heads. Image courtesy of Agnew Analog Reference Instruments.

Sapphire cutting stylus installed in Agnew Analog Type 1501 long shank adapter for use in vintage monophonic cutter heads. Image courtesy of Agnew Analog Reference Instruments.But how accurate do we need to be?

This largely depends on what degree of reproduction accuracy we are aiming for. There are multiple other factors that can compromise accuracy such as the other geometric aspects of cartridge alignment, tracing errors originating from the playback stylus shape, as well as phono stage issues, so unless we are prepared to deal with all of them, SRA/VTA variations of, say, a second of an arc are going to be largely masked by other effects. The more accurate the rest of your system is, the more it will reveal the effects of such variations. The means (and patience) to determine angular errors of less than a degree is simply not available in commercial phono cartridge manufacturing and are mainly to be found in standards institutes, laboratories, and perhaps the homes of some foamingly rabid audiophiles (the author pleads guilty as charged)…!

Audio-Technica AT-ART9XA phono cartridge.

Audio-Technica AT-ART9XA phono cartridge.