Grooved media – phonograph cylinders, gramophone records and so on – kickstarted the recording industry and were the dominant commercial recording and playback formats up until the Second World War. However, long before WWII there were a number of developments which led to the advent and commercialization of magnetic tape recording as we now know it.

Wire recording dates back to 1898 and early experiments by Danish engineer Valdemar Poulsen. His efforts yielded the Telegraphone, which recorded a signal on a spool of steel wire by guiding it past a recording head, which magnetically stored the information on the wire. If guided past a playback head capable of converting the wire magnetization into an electrical signal, the recording could be reproduced. Then came steel tape and the Marconi-Stille tape recording system, used in the 1930s.

“One of the Blattnerphone BBC recording machines on which the programs are recorded by a magnetic process for Empire broadcasting.” February 1937

While coated plastic tape had already been invented by 1928, it was not widely used until the 1940s with the development of the Magnetophon system in Germany by AEG. The basic principles of magnetic recording are the same for all the various systems, but the real breakthrough of the Magnetophon was the combination of plastic-base tape with AC bias, which provided vastly superior sound quality along with the ability to easily cut and splice tape for editing purposes. AEG introduced the K1, the world’s first practical high quality tape recorder.

After the war the Magnetophon technology was brought to the US by Jack Mullin, who had served in the U.S. Army Signal Corps in Germany and obtained two of the recorders before returning to the US. He improved the machines to the point where, thanks to his efforts, an entire industry was created based around the various commercial uses of magnetic tape recording technology.

Tape editing in action. Photo courtesy of Magnetic Fidelity.

One very convenient aspect of plastic-backed tape is that it can be easily manufactured in different widths, coated with different types of magnetic oxide particles, run at different speeds and divided into multiple tracks. This last point deserves further explanation. The tape itself is not actually physically divided into tracks. The entire width of the tape is uniformly coated with magnetic particles. As such, the same tape could have one “channel” of information recorded across its entire width, or two channels recorded in parallel, one next to the other and each occupying half the width of the tape, or three channels with each occupying 1/3 of the width, or even 24 channels, with each occupying 1/24 of the width!

It is the configuration of the magnetic heads on the tape machine that define how the tape is to be utilized. For example, 1/4-inch tape was used for the commercially available reel-to-reel tapes of the 1950s and 1960s. Monophonic tapes commonly contained two tracks (referred to as half-track mono) and stereophonic tapes had four tracks (quarter-track stereo). After playing one side, the tape was flipped over to play the other side.

The same 1/4-inch tape was also used for four-track tape recorders such as the classic TEAC A3340S, which enabled musicians to create high-quality multitrack recordings at home in the 1970s. Same tape, different magnetic head configurations.

NAGRA IV-S; Photo courtesy of George Vardis.

An aside for historians and archivists: while it is convenient to be able to use tape in different ways, this leaves us with a challenge: Given an undocumented reel of tape, it is impossible, without considerable effort expended in trial and error, to tell how many tracks (channels) have been recorded on its surface, at which speed it is meant to be played back, what equalization should be used on the playback electronics, if any form of noise reduction system has been used which would require decoding, or even what kind of program material the tape is meant to contain!

The practicality and stability of the tape recording process made the technology incredibly popular. In fact, it enabled the very existence of recorded music as we know it today and the advent of the VCR (VideoCassette Recorder) in the 1970s. Tape recording also found application in a wide range of other fields, some of which had nothing to do with audio.

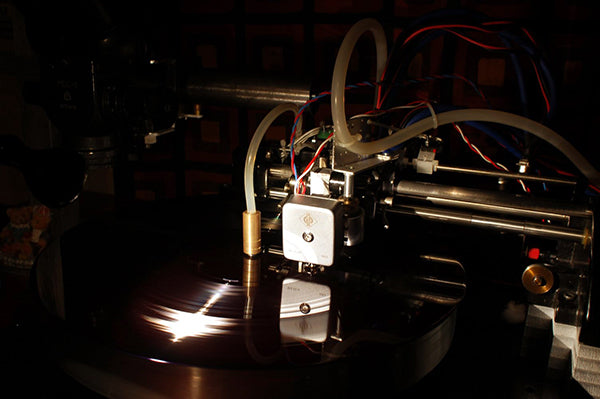

Aside from recording studios and home entertainment systems, tape was quickly adopted by the broadcasting sector, replacing disk recording/reproducing systems not only as a means of playing back music and recording programs, but also for 24-hour logging of a station’s output. Prior to tape, a considerable industry existed for the purpose of supplying disk recording lathes for 24-hour logging. That industry disappeared as soon as tape machines entered the broadcasting market.

Tape was also very widely used in television and film, not just for sound recording but also for video recording in the form of the VTR (VideoTape Recorder) and eventually VHS (Video Home System) and other formats. In the film industry, magnetic coatings were used on the film itself to magnetically record the soundtrack onto the film in sync with the image. In a different sound-on-film process, the audio track can also be optically encoded onto the film, but this is another story. Cartridge-type formats such as the 8-track cartridge and the cassette tape were also eventually adopted by the broadcasting sector as well, alongside many other tape formats.

VHS tape

On the consumer side of things, commercially available albums first appeared as monophonic tape reels at 3.75 ips (inches per second), then evolved into stereophonic formats at 7.5 ips and eventually became 8-track cartridges, cassette tapes and other little-known formats. (Who else remembers Elcaset?)

Studer A80; Photo courtesy of George Vardis.

Tape machines also found use as instrumentation recording devices in industrial facilities, for logging purposes, process control and other applications. They were widely adopted by the aerospace industry as on-board flight data recording systems.

Tape also became popular for the storage of digital data for computer systems, in various different formats including DAT tape, open reel systems and even cassette tape. Users of Commodore 64 and other computers of that era can shed a tear of nostalgia here. The hard disk drives used for data storage applications in computers and external drives are very similar to tape in operating principle since they’re also magnetic recording devices.

DDS2 digital storage tape

In addition, various tape formats have been used in telephone answering machines, call centers and many other telecommunications applications.

In recording studios (back to talking about audio), the first tape recorders were monophonic, moving on to two-track tape machines for stereo recording or overdubbing. Throughout the 1960s and 1970s came 3-track, 4-track, 8-track, 16-track and 24-track multitrack tape machines on wide-format tape. Typically, the 16-track and 24-track machines use 2-inch tape. The multitrack tape machines allowed musical instruments to be recorded individually at different times and places (overdubbed), layered, or doubled, often in ways which would not be possible in a real-time live performance.

The 24-track, 2-inch tape machine, having a track width equivalent to quarter-track stereo on 1/4″ tape, or a bit less than double the track width of a stereo cassette tape, was the largest number of tracks considered acceptable from a quality standpoint for professional recording. As such, this was the largest number of tracks offered on professional tape machines by commercial manufacturers. Larger numbers of tracks have been seen, but never became popular in the analog domain.

The multitrack tapes would then be played back, with each track directed to a separate channel of a multichannel mixing console to be combined to two channels (left and right for stereo) and where processing such as equalization, compression and other effects could be added, which is similar to the way recordings are made nowadays. This two-channel output would be sent to a two-track tape machine which would record the stereo mixdown onto a stereo master tape. The master tape would normally be copied a few times to make safety copies or production masters to be sent off for disk mastering, perhaps in many different countries.

RCA 1/4″ Tape Cartridge

Copies on cassette tape would be made for the producer and artists to take home and from the 1980’s onwards the master tapes would also be digitized onto DAT tape, or U-matic tapes as used with the Sony 16xx series of machines, then considered to be the industry standard medium for transferring the digital audio information to the glass masters used in CD manufacturing.

Throughout the 1980s a number of open-reel digital tape sound recording systems were introduced, along with DAT (Digital Audio Tape), DTRS (Digital Tape Recording System) and various other cassette-shell tape formats, all of which have faded into obsolescence by now.

Most recently, commercially available open reel tapes have been enjoying a resurgence among audiophiles, usually in the form of copies of master tapes on 1/4″ tape at 15 ips. These releases can offer extremely high sound quality if done properly and really are genuine copies of the original master tape. However, it’s important to verify, if possible, the provenance of so-called master tapes. For example, many tape archives have been found in warehouses, or among the auctioned assets of bankrupt record labels, pressing plants and broadcasting facilities. These are often 5th generation production masters, recorded with signal processing for cutting lacquer master disks or for cassette tape duplication. They are far from the original master tape in terms of sound quality.

Naxatras III Copies of Master Tape on 1/4″ reel-to-reel tape. Photo courtesy of Sabine Agnew, Magnetic Fidelity Recordings.

To not leave out some oddities, tape was also used in dedicated tape delay units used by recording studios and musicians. These units were equipped with multiple magnetic heads to record and play back a signal multiple times, creating multiple repeats. Normal tape machines can also be converted for special effects, something which I have personally enjoyed doing on several occasions in the studio.

Here is an example of tape effect on the vocals, done in real-time as the band was performing, by manipulating the tape by hand. A second tape machine was recording the outcome.

Tape machines have even found use in recording control voltage signals from modular synthesizers; the tape can then be played back to control the synthesizer instead of playing the synth in real time. In fact, this along with obsessive tape editing, tape loops and other techniques, developed into a dedicated genre known among aficionados as “tape music.”

Tape loop inside tape delay unit. Photo courtesy of Magnetic Fidelity.

However, by far the most popular application of magnetic recording is the most mundane one: That little brown strip on the back of your credit card, debit card and others like it. It’s a small piece of magnetic recording material.

Carefully stored, magnetic tape is one of the most durable and stable media for long term archival storage of anything important, from valuable sound recordings to critical digital data. That said, its ultimate shelf life still remains to be determined. It is reassuring that my own collection of 1950s tapes shows no sign of deterioration in 2019.