Somewhere back in the last century, from around 1976 to 1983, a California company called Pacific Recorders & Engineering (PR&E) designed and built tape cartridge machines for radio stations. One PR&E model, the Tomcat (an acronym for Theory Optimized Microprocessor Controlled Audio Transport, if you can believe that), was said to be more durable and have better S/N and better sound quality than anything else on the market. Cart machines were used for easy playback of commercial spots, as well as for music.

PR&E branched out into amplifiers, microphone preamps and mixing boards for broadcast and recording applications, and their reputation for high performance and durability spread. Occasionally, audiophiles would stumble upon a PR&E amp, and again, the company’s reputation spread.

As have zillions of Californians before him and since, company head Jeff Nelson relocated to Colorado in 1984. The company was housed in an old farmhouse in Superior, south of Boulder, Colorado, and the company was renamed Boulder Amplifiers.

Soon thereafter, the company’s focus shifted from pro gear to high-performance consumer products. A pro-model amp, the 500, featured the standard pro-style indicators and controls on its front panel. The 500 AE–”Audiophile Edition”—deleted the gewgaws and had only a power switch.

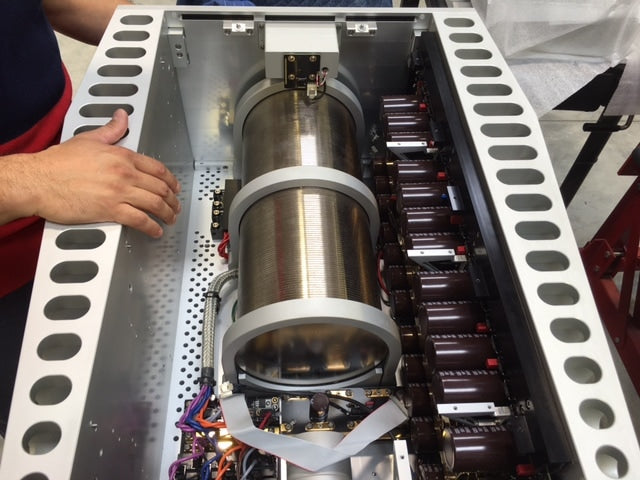

For over 30 years now, Boulder has designed and built indestructible amps, preamps, and other components. Products feature impressive, heavily-machined casework that is all done in-house, a rarity these days. The impression given by their products is a sense of being built for maximum performance and durability with cost no object.

The company’s new, purpose-built 23,000 square foot facility in Louisville, Colorado will allow the company to pursue even bigger/better/badder projects. It’ll be interesting to see what they come up with!

Special thanks to Rich Maez for the tour.