When thinking of the ultimate cassette deck, many people think of Nakamichi. The company made some of the most impressive cassette decks ever. They were used by audiophiles and professionals, but were rarely found in professional recording studios for capturing audio. The Nakamichi 1000 was popular with not only audiophiles but also with computer programmers in the late 1970s. It was used as a deck for recording computer data to cassette tape, for use by the Commodores, Ataris, Amstrads and other computers of that era. While these computers had their own cassette decks, they were often cheaply made and not considered reliable for recording data for critical uses.

The industry standard for professional recording studios became the Tascam 122. This is a real workhorse of a cassette deck, reliable and easy to use. Many recordings throughout history first left the studio as copies dubbed from the master tape onto cassette tape, made for the producer and musicians to listen to at home, and for radio stations to be able to play on the air before the album made it to store shelves.

Tascam 122 mkII cassette deck. Photo courtesy of Magnetic Fidelity.

In the pre-digital era there were only three formats you could conceivably take home after a studio session: A reference acetate disk, a reel of 1/4-inch tape, or a cassette tape. The reference acetate was cut on a disk recording lathe and could be played back on any record player. Being softer than a vinyl record, it would withstand only a few plays before the sound quality would degrade unacceptably through wear. However, while it was a simple task to play an acetate disk back, not many recording studios after the 1950s had disk recording lathes. Reference acetates would therefore mainly be cut at specialist disk mastering facilities from the 1960s onwards.

While 1/4-inch tape was a popular studio format, the tape was expensive and the machines were even more expensive; very few people had a 1/4-inch tape machine at home that was capable of playing 10.5-inch reels at 15 inches per second (ips).

On the other hand, cassette tape was cheap, most people had cassette decks at home and in the car, most recording studios had a professional deck to record on and even radio stations could play it! Yet for many years, other than being a consumer format, in the professional world cassette tape was nothing more than a temporary copy of the “reel thing,” used for convenience. Professional recording facilities were not keen on using cassette as the primary recording medium at first, although it was used as such in home studios.

However, the demand for low-cost demo recordings saw many recording studios eventually putting their cassette decks to use, for recording unknown bands on cassette tape. These demo recordings were not intended for commercial release. They were just copied and passed around to friends, family and record label A&R people in hope of the band being discovered and offered a “proper” recording on reel-to-reel tape.

All this was based on the assumption that cassette decks could not compete with reel-to-reel tape machines in terms of performance. But, what if I was to tell you of a cassette deck that had a flat frequency response all the way to 27 kHz, ran at 3.75 ips and could put to shame even some professional reel-to-reel machines? No, it is not a Nakamichi. It is actually a heavily modified version of the Tascam 122! It was not modified by Tascam or any other large corporation, but by an individual: Alex Nikitin.

He took a Tascam 122mkIII, made it run at 3.75 ips, removed the Dolby noise reduction circuitry, replaced a lot of the audio circuitry and components, set the EQ to 50 µs and developed what is, in effect, the world’s best-performing cassette deck.

Tascam 122 mkIII m9 high speed cassette deck, modified by Alex Nikitin. Photo courtesy of Magnetic Fidelity.

I would love to tell you that this deck was immediately adopted by recording enthusiasts the world over, but it wasn’t. It could only record around 15 minutes per side of a C60 cassette and with the non-standard EQ, it is incompatible with anything else. Cassettes recorded on this machine can only be played back on this machine. Nevertheless, as soon as I found out it existed, I ordered one. I took delivery of it in 2014 and got to work recording the impoverished artists of Southeastern Europe on cassette tape.

One of the bands that found their way to my studio, Magnetic Fidelity, at the time was rather unusual. They had almost no money and just wanted to “hear how they sound.” This band I’m referring to had no intention of making a professional recording! This was their first time in a studio. However, they were unusually serious and determined despite their young age. As soon as they started playing, I knew the album would become a hit, and was glad the cassette deck I used for the recording was the best there is, because it would have to be up to the task!

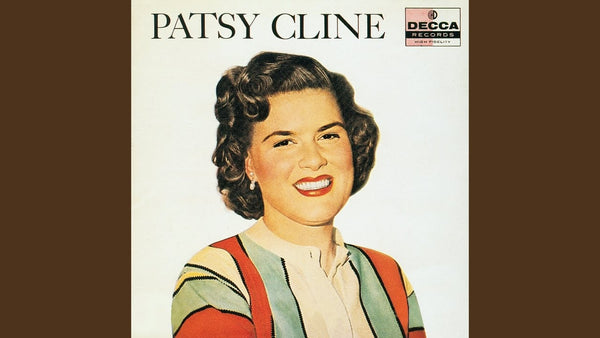

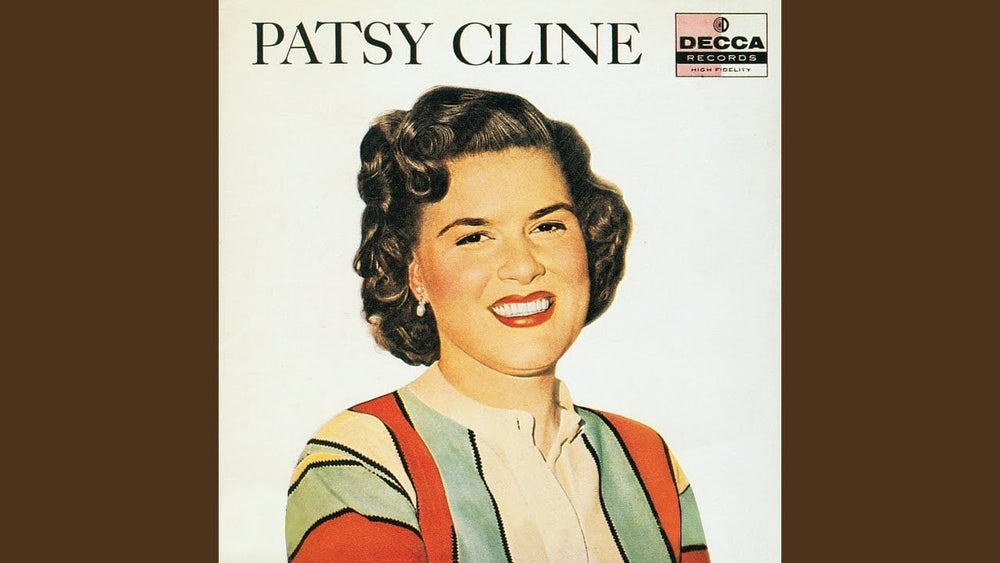

Not only did that demo recording become a commercial release, on multiple formats, it also became a commercial success, establishing the band Naxatras internationally. The cassette tapes have yielded lacquer masters for a double LP release, a cassette tape release, a CD release, high-res 192/24 digital downloads and even DSD-format versions at 2.8 MHz and 5.6 MHz.

https://www.youtube.com/watch?v=WNjyvtjAmUo

The Naxatras debut LP, recorded on cassette tape. Photo courtesy of Magnetic Fidelity.

https://www.nativedsd.com/albums/NXTRS01-naxatras-lp

https://naxatras.bandcamp.com

https://fwrlrecords.nativedsd.com

Few people realize that this album was recorded on cassette tape, in the space of only a few hours!

The cassette tape version of the first Naxatras album. Photo courtesy of Magnetic Fidelity.

As for many of my cassette recordings, I used Maxell XLII-S tape stock, loaded in custom high performance shells. The cassette shell mechanism forms part of the tape transport system, so its performance is an important consideration.

To eliminate any problems with the cassette shell, commercially available prerecorded cassettes were usually created by bulk high-speed duplication. The tape would be recorded in large “pancakes,” both sides recorded in one pass as 4 channels of audio (two playing in reverse) at high speed, without being in the shells. Each pancake would contain multiple cassettes worth of tape, recorded sequentially, usually with an ultrasonic blip at the end of each cassette to mark where the pancake should be split. If you look carefully, you can sometimes even see the meters on some cassette decks reacting to something inaudible at the end of a prerecorded cassette. (It’s the blip, Frank, it’s the blip!)

Gauss tape machine for recording 1” master tape loops for industrial cassette duplication. Photo courtesy of Nicolas Garofallou.

The duplication master was a loop of 1/2-inch or 1-inch tape, containing an entire album as 4 tracks, playing in a loop, over and over again, on a special high speed tape machine called an analog loop bin system.

The audio from the loop bin went to the high speed duplicator, which recorded the audio on pancakes of 1/8-inch tape. The recorded pancakes, along with empty cassette shells, were then placed in a cassette loader, which loads the tape in cassette shells.

Tapematic 2000 tape loader, used for loading the recorded pancakes into cassette shells. Photo courtesy of Nicolas Garofallou.

The more advanced loaders had a system which detected the ultrasonic blip at the end of each cassette, stopped the loading, cut the tape, and started over again with a new shell, with the process completely automated.

Eventually, analog loop bin systems were replaced by digital loop bin systems, where the loop was no longer on tape but in the digital domain, as a digital file played back on repeat.

Gauss analog loop bin for industrial high speed cassette duplication. Photo courtesy of Nicolas Garofallou.

Are the high speed industrial tape duplication systems superior, in terms of sound quality, to what can be achieved by recording on a cassette deck? Probably not, especially if high-quality cassette decks such as the Tascam 122, Nakamichi 1000, or any other selection from a wide range of high-quality machines by different manufacturers are used, along with high-quality tape stock loaded in high-quality shells. With a 1/4-inch reel-to-reel master tape as the source, excellent sound quality can be achieved. The productivity, however, is dramatically lower (it takes much more time to produce fewer tapes), causing the costs to skyrocket. The affordability of prerecorded cassette tape was made possible by the productivity of industrial high-speed duplication systems, even if the resulting sound quality was often less than spectacular.

Cassette tape is capable of very high-quality sound if used carefully and with the right equipment. And although cassette tape manufacturing had completely ceased for some years, with the remaining global demand served exclusively from remaining blank cassette tape stocks, cassettes have made enough of a comeback that ATR Magnetics has recently announced they have started manufacturing their own cassette tape! At present, they are offering ferric oxide (Type I) tape, based on their excellent reel-to-reel tape formulation, as C60 and C90 cassettes! ATR Magnetics, located in York, PA, is one of the only two remaining manufacturers of professional reel-to-reel tape for the recording industry. Although they have been manufacturing 1/4-inch, 1/2-inch, 1-inch and 2-inch tape for several years, with multiple award-winning albums recorded on their tape, these are their first-ever cassette tape products.

The brand new ATR Master Cassette Tape (C60) and MDS Cassette Tape (C90), both being Normal Bias Ferric Oxide Type I tapes. Photo courtesy of ATR Magnetics.

I would strongly encourage anyone interested in learning the art and science of sound recording to start with cassette tape, even nowadays.

It is great fun, offers a value for your money that is hard to beat and can reward you with excellent recordings. From a toddler-friendly format to a portable format for the Walkman or the car; from mixtapes, to demo recordings all the way to commercial releases, the cassette tape is versatile enough to do the trick.

As with reel-to-reel tape, in terms of longevity, the tape itself can last incredibly long. The weakness of the cassette tape, however, is that it carries with it a part of the mechanical transport system (the shell), which is what would probably break long before anything happens to the tape itself. I have successfully transplanted tape to new shells, giving it a new life, but it can be a fiddly task.

The other enemy of cassette tape is cheap cassette decks that tend to wear out or go out of adjustment and start chewing up perfectly good tape. Use good decks, keep them in good shape, and your tape collection will live much longer.

But, is it really making a comeback?

Well, a rather shy one, considering that cassettes were once the most popular format (surpassing LP and CD sales), but yes, it is certainly experiencing a resurgence. However, the technical expertise in all aspects of magnetic tape recording technology from servicing and maintaining existing equipment to designing new machines, from making calibration tapes to offering specialized measurement instruments, from manufacturing tape and shells to even actually using cassette decks properly, is hard to come by nowadays.

In my opinion, this is what will make or break the format in the long run. If we succeed in passing on this knowledge to the younger generations, cassette tape and other formats will survive. If not, cassette tape will die out along with the few remaining experts in the field.

Header Image: Nakamichi 1000 cassette deck. Photo courtesy of Thomasz Gaca.

(Photos of Steve Waksman by Julian Parker-Burns.)

(Photos of Steve Waksman by Julian Parker-Burns.)