In our first installment of this series we looked at the first step in getting a product to market: the initiation process. At this point the company has an idea of what the product is, what problem it is solving and the ways in which it will make customers happy. In some cases, those involved have some firm ideas of what it will do, what features and functions it must have, perhaps some clear idea of what parts and materials it should be made of, and even where and how much it could cost to make.

All of this is the result of weeks or even years of experimenting, testing new parts, and perhaps implementing new technologies, design approaches, software, you name it. Few products are built from the ground up; most are made on the shoulders of what has come before, but make no mistake, a lot of work has gone into getting here. Now it’s time to actually make something.

This is also the point where the process broadens. It will take many “shareholders’” work and approval to move forward. What drives this stage is the formal definition of the product, as embodied in the PRD or MRD (Product or Marketing Requirements Document).

This is not as straightforward as you may think. You may have defined all you could wish for in a product, but then there are those little considerations such as: what will it sell for and what will it cost to make? Who is supposed to buy it? How many of these folks are there? How will we reach them? What should it look like? How and where will we actually build it? How will we sell it? What about ecological, safety and other considerations?

Each of these decisions will affect the other product parameters, and you now have to define your project down to the last detail to get the answers to the questions posed above.

The next step is to ask all the constituent stakeholders about the project. These can include possible customers, trade partners like retailers and distributors, professional reviewers, your competitors (though perhaps not directly), your sales staff, finance folk, investors, factory partners, parts suppliers, logistics services and industrial designers – essentially everyone who may be involved.

Asking all these questions is important in order to have confidence of some measure of success. A mismatch of expectations can lead to a failed product. The statistics on this are not good; far more products fail in the consumer electronics and audio spaces than not, and at worst this can cost the life of a firm and the dream of the person behind the product.

Potential customers can tell you what they like and don’t like about you and your competitors’ current products. Retail and distribution partners have insight as to what sells. They also understand the business side of things and their input on the proposed selling price, the perceived value and the number of potential customers will be important. Professional reviewers can sometimes sting with their criticisms, but their input is valuable in constantly pushing the edge. And while competitors will not likely disclose their approaches, you can find out what they’re doing by buying and examining their products and asking customers what they like and don’t like about them.

Internally you should have input from all company departments. Sales, your “feet on the ground” in the market, will tell you what is selling and what is needed. While sales teams may not have the expertise in product development that, say, engineering and production have, they know what they are going to need to actually sell the product in the real world.

The financial people will want to know how the potential product will contribute to the firm’s bottom line. How much profit can be expected, and what amount of capital and other expenses will be required to produce the new item? Businesses need to operate well and make profits to pay their employees and cover expenses. As finance asks these questions, it drives a lot of other effort into finding out what all the dreams, ideas, materials and approaches will actually cost. Estimates will need to be prepared and as real figures come in they will be compared to the estimates, and likely alter the original plan in many ways.

As previously noted, the other functions of the company will also be called in for input on everything from figuring out how to ship the product to giving it a name.

Now we come to the areas that most people think of in making a product: the engineering and production. The road up to this point may have been rocky, with even arguments and insults tossed. For example, the person with the original idea may feel like others in the company don’t understand his or her vision or are trying to compromise it. But at this stage we have to expand the playing field yet again, as a lot of engineering disciplines will now come into play.

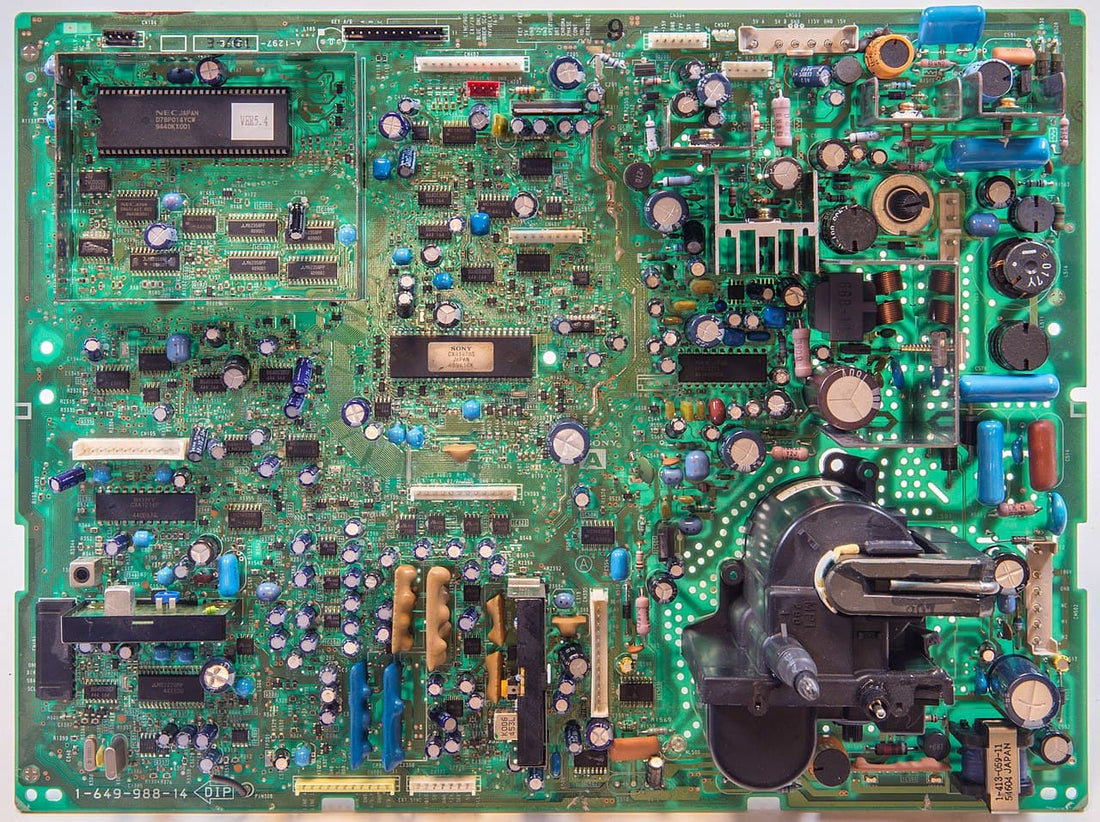

Although there are a few “renaissance” people in the world with a grasp of multiple disciplines, most new-product development requires a team effort, sometimes involving a very large and complex group. Depending on the product we may need expertise in mechanical engineering, circuit board design and layout, digital signal processing, RF engineering (for Wi-Fi, Bluetooth or other aspects) power supplies, amplifier topology, acoustic engineering, driver design and more. Then there are considerations of testing and verification, designing for manufacturability, and safety, standard and environmental compliance. And this is not even a complete list. In today’s connected world you may also have to test that it properly interacts with and can be controlled by third party software, digital voice assistants and the like.

Do you have all these skills in-house? Often as not, even giant firms have to engage the services of skilled subcontractors.

On top of all this, the product needs to have an appealing and functional industrial design, which often requires the work of an outside designer or firm. The late and sadly missed Allen Boothroyd comes to mind. He not only created beautiful and useful products at Meridian Audio (along with Bob Stuart) and at speaker manufacturer KEF (where I had the pleasure of working with him), but also designed numerous other consumer electronics products from computers to coffee makers.

The Meridian Special Edition DSP8000 loudspeaker.

A great ID firm can really help, but realize they can be expensive. However, the results can be worth it. I worked with design firm IDEO on iPod speaker docks when I was at Altec Lansing. IDEO conducted an in-depth study to understand how and where people wanted to use their iPods and associated speaker docks. We gained invaluable insights – which resulted in the sale of millions of Altec Lansing iPod speaker systems.

The next step is to create a Bill of Materials, or BOM. Pricing of all the materials that go into a product is of course a major consideration, and the pricing may be affected by the quantities to be purchased, whether they can be bought “off the shelf” or have to be made, whether parts from previous products can be used, and other considerations.

If you are a small manufacturer this process is not so easy. You may end up buying in small lots with high prices with little idea of what volume price reductions you might be able to take advantage of if you sell more units than originally planned. One of the reasons that some of the most interesting and hand-built audio components and speakers cost so much is that parts cannot be bought at volume discounts.

In the case of parts machining, for example, there is a fixed set-up charge that is the same whether you order 10 parts or 1,000. Building a loudspeaker? If your sales volume is, say, only a few hundred speakers you may have no other choice but to go to a small cabinetmaker, as volume-loudspeaker OEM/ODM (original equipment manufacturer/original design manufacturer) factories rely on making large quantities in order to scale up their production lines.

A CNC (computer numerically controlled) machining facility. Courtesy of Wikimedia Commons/Antoniusaw.

The industrial design of the product will call for various materials and finishes. These will be a costly aspect of the product – but often are the key to selling it. Keep in mind that items like gold-plated connectors may be considered an essential selling point, regardless of whether the designer considers them necessary for performance. And so it goes; all of the various parts needed must be sourced and priced. These all add up to the estimated BOM – and usually it is more, often far more, than planned.

This leads to another round of discussion (or argument) over what is really important to the success of the product. If holding the price is key, then everyone looks for compromise. For example: Scan-Speak speaker drivers are truly extraordinary, but so is their cost, so perhaps another alternative would do. Rosewood is beautiful, but there are less expensive and more sustainable options. Key parts may have been tested in the development and initiation phases, but now they will be scrutinized regarding which ones can and cannot stay in place. For luxury items, price is often the variable that changes – it goes up. (Which sometimes leads to expensive audio components becoming the subject of ridicule, but that’s another subject.)

A Scan-Speak 18M/8631T00 midrange driver.

The need to reduce costs can also lead to less-expensive marketing campaigns, smaller profits or other changes to the initial plan. None are easy choices, but consider: if no one knows about your product because of a reduced marketing campaign, then no matter how good it is, it may be passed by.

As the discussion and horse-trading continue the BOM may be more finely tuned and costs brought more into line. Perhaps production methods can be changed. One of the items we produced with IDEO needed to be strapped together in production in order to be assembled. It required special rigs and slowed down production a lot. Over time a better assembly method was put in place, which not only led to lower cost but better quality. This can be especially true in television manufacturing, which is one reason why their prices have fallen over the years.

And round and round we go, with each group (engineering, finance, sales, marketing and so on) bringing back their findings and their effects on practicality and cost. Ultimately a final decision is made where the product specs are set.

But even here, when we begin to pull the trigger, we are not done. Do all the parts and subassemblies fit together? Does everything work properly? The truth is, the product is still not final, but we have to get things going, so now we ask all the various departments to give us final parts lists, Gerber files (printed circuit board image files), lists of materials and everything else needed to go into the actual production phase.

We will run through this next gauntlet in the following article.

Header image courtesy of Wikimedia Commons/Hannes Grobe.