Over the past 130 years or so, very little has changed in disk recording, mastering and record manufacturing. The shift from acoustic recording to electrical recording took place in the 1930s, the transition from wax blanks to lacquer blanks happened shortly thereafter, and that was followed by the introduction of vinyl as a material for pressing records, which replaced the Flintstones-esque ground slate with shellac as a binder that had been used extensively up until the 1940s. The final big change occurred in the late 1950s, with stereophonic records beginning to take over the market. However, even the early acoustic recording era shellac pressings still follow the exact same underlying principles as modern stereophonic vinyl records.

Looking at the bigger picture, the disk record is by far the longest-standing information carrier in the entire history of sound recording and the media industry. The manufacturing side of this business is one of the most stubbornly conservative sectors in industry that the world has ever seen. The majority of this industry still relies on machinery manufactured around 70 years ago. The presses would make any serious steampunk enthusiast weep with joy, as they are still steam-heated, water-cooled and rely on high-pressure hydraulics with nitrogen accumulators for their operation.

Steampunk appeal aside, disk records have always been a horrible medium to manufacture! It is incredibly difficult to make a good record, and taming the archaic behemoths required to make records is not a task I would wish upon anybody. It is, quite frankly, a terrible job! Stressful, time-consuming, physically and mentally exhausting, and quite a liability in case anything goes wrong. Why would anyone make records, when, with far fewer skills, they could be a head of state, get paid much more, do far less, and never have to be held accountable for messing things up?

If it wasn’t for a well-made record offering one of the most rewarding auditory experiences one could possibly have, nobody would be making them!

Nobody! The entire industry was ecstatic when the CD finally caught on, and they didn’t have to suffer through the disk mastering, electroplating and pressing stages for vinyl records anymore. In some cases, record presses were even ceremonially dumped in the ocean, with irate record label executives screaming, “so long, and thanks for all the fish” as the multi-thousand-pound chunks of cast iron went splash. If it were up to them, these presses and all the disk mastering lathes in the world would forever decorate the deepest abyss of the deepest ocean. They would even mark the exact spot on a map and pass it on to their head of state friends, as a potential site for the underwater detonation of nuclear warheads, for purely “scientific” purposes, of course.

Unfortunately for such individuals, while the future looked bright for a while and everyone was getting excited about the possibility of throwing all the CD manufacturing equipment in the sea as well, marking the end of the cumbersome, complicated and not-as-profitable-as-it-could-be physical distribution of media, to be replaced by digital distribution models, the market suddenly decided otherwise. The demand for vinyl records started rising again, and along with it, the severity of heartburn among those in the industry who had been more than happy to contribute steampunk sculptures to marine ecology. The vinyl record is now back with a vengeance, but the manufacturing process is still as archaic, complicated and demanding as it has always been. But is this part of the appeal?

Günther Loibl didn’t think so. He founded Rebeat Innovation GmbH in 2017, with the aim of dragging vinyl record manufacturing out of the steampunk era and into the space age. He called his idea “HD Vinyl.” By 2018, Rebeat Innovation GmbH had attracted $4.8 million in investment capital to develop the new technology required to turn his idea into an actual product. Günther Loibl and Rebeat Innovation GmbH were based in Tulln, Austria, not far from Thal, the birthplace of Arnold Schwarzenegger. If Arnold could become the Governor of California, then there is nothing that could stop Günther from becoming the King of Vinyl, or its Terminator! Or, as it turned out, neither of the two.

But, how would he change the manufacturing process? What is HD Vinyl? The idea behind HD Vinyl was to entirely eliminate the process of disk mastering, which has traditionally involved cutting a master disk on a lacquer blank. The lacquer master disk would then be electroplated to create a negative (the term here used in a context similar to a negative in film photography), which would have ridges instead of grooves. The negative would be made of nickel and could then be used as a stamper in the molds of a press, to stamp out thousands of copies of a vinyl record. HD Vinyl would also eliminate the electroplating process. Instead, the idea of HD Vinyl was to directly create the stamper, bypassing several manufacturing stages (and the associated costs, as well as the possibilities of things going wrong).

Günther Loibl proposed cutting the stamper using laser technology. Over several years, the company attempted to prove that this would be technologically viable, but did not succeed in presenting a functional solution. While CNC laser-cutting technology is in a mature stage and in widespread use in various sectors of industry, it is not normally suited to applications requiring high precision and a good surface finish. The commonly-encountered laser cutting systems produce a surface finish in the 3-digit micrometer range and accuracy in the low micrometer range at best, while for a successful record groove (or ridge), a surface finish in the very low nanometer range is required, with accuracy in the picometer range! Furthermore, laser cutting is typically a two-dimensional process. The laser removes material straight down from where the lens is aimed. However, the material removal process, whether due to thermal evaporation or ablation, is hard to control geometrically in a three-dimensional space. In industrial applications, laser cutting is used where geometric accuracy is not a critical parameter. In a record groove, or stamper ridge, the geometric accuracy is certainly a most critical parameter.

In addition, all cutting, material removal, or even most additive manufacturing operations produce unintentional “tool marks” that disturb the surface finish to some extent. Any given surface will only appear to be flat until you use enough magnification to see that it is not flat. This is a fact that metrologists are intimately familiar with. With the conventional disk mastering process, where the groove is mechanically cut on a lathe, the inevitable tool marks are in the direction of the cut. The playback stylus is therefore unable to trace them. In laser cutting, however, the “tool marks” are in the direction of the laser beam, which is at right angles to the direction of cut. The playback stylus would therefore trace then, unless they were made infinitesimally small. The biggest obstacle to turning HD Vinyl into reality would be that the technology to enable the cutting of stampers using laser does not yet exist, and it is not yet certain if it could ever exist. The whole project was enormously ambitious in this respect. It was not a case of adapting existing technology for a new purpose, but a case of starting from scratch and developing the technology required to produce a stamper in this manner.

The material of the stamper was also an important consideration, and Rebeat soon decided to use a ceramic material instead of nickel, most probably in hope of achieving a higher degree of accuracy in the cutting operation. The thermal properties of a different material, even if a stamper could be successfully cut on it, would not necessarily make it possible to use on a typical record press to produce vinyl records. There were countless technical challenges and plenty of uncharted territory to be explored, but the company ran out of funds and filed for bankruptcy in August 2022 (just a few days before this article was written), without having demonstrated their proposed technology, or that it would even be viable at all as a concept.

What they did do was to create some of the simpler aspects of the process. Rebeat Innovation GmbH developed software that would generate a topographic map of the groove/ridge structure on a disk, as a sort of complex CAD (computer aided design) drawing to be used in interfacing with the CAM (computer aided manufacturing) software that would control the CNC (computer numerical control) part of the laser cutting equipment. They also developed software that was essentially a virtual model of a Neumann VMS-80 lathe, which would virtually cut a record and tell you where the problems would be if you were to cut that material on an actual record, using a conventional mastering lathe. The latter appeared to be a diversification attempt, in case the original idea of HD Vinyl did not work out.

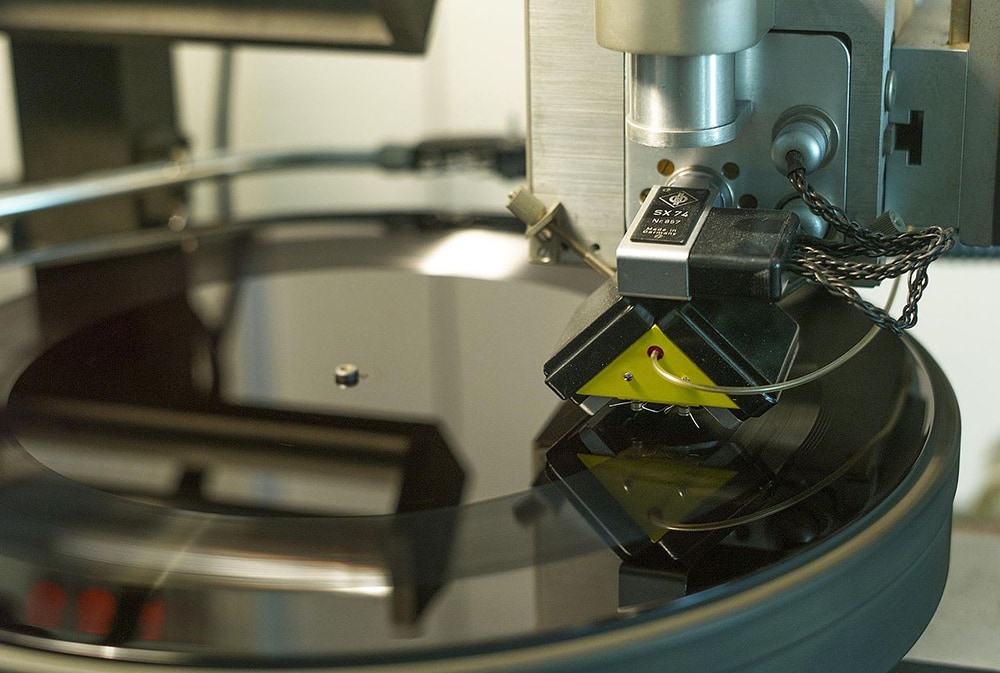

It’s not easy: cutting a record on a Neumann VMS-80 lathe with a Neumann SX 74 cutter head. Courtesy of Wikimedia Commons/Rainer.Maillard.

Even if the technological hurdles would be overcome, HD Vinyl would primarily succeed in potentially lowering the manufacturing cost of vinyl records while eliminating the need for some of the skilled workforce that would traditionally handle the cutting and electroplating. Their claims of louder and longer sides were debatable, considering that even with 1930s technology, it was possible to cut records loud enough that no modern playback equipment would be capable of reproducing.

The entire process would of course be software-based, requiring the audio to be presented in a compatible digital format. DSD would likely create difficulties unless converted to PCM and all analog formats would need to be converted to digital for this concept to function. As such, HD Vinyl would never be able to replace all-analog tape-to-disk transfers that are still done to this day, resulting in some of the finest-sounding records I have had the pleasure of listening to (recent events in this sector notwithstanding, there are companies out there that do genuine all-analog disk mastering directly from the original master tapes). HD Vinyl would also never be able to do direct-to-disk recording, so it would not really be a replacement for the finer pleasures in grooved media! However, as evidenced by the success in securing investment capital, there is a very active interest in lowering manufacturing costs and eliminating as much of the complexity as possible from the manufacturing process.

Industry people were divided in two camps over this. Many were very skeptical and suspicious right from the start. Many seasoned veterans of vinyl record manufacturing tended towards the opinion that the proposed technology is not actually realistic. Many avoided public comments, while others were far less diplomatic, and the hashtag #hdvinylsucks started appearing on Instagram. On the other side were those who believe that all new ideas were not considered possible at first, and that if innovation is to be encouraged, it is the crazy big impossible ideas that should be supported (and funded with large sums).

While the latter opinion is valid to some extent, the former group were also skeptical of such ideas originating, not within the industry, but with someone who had little contact with the nitty gritty of the manufacturing process prior to this venture.

In fact, on August 19, 2022, an article by Paul Resnikoff on digitalmusicnews.com, quoting Günther Loibl, stated that the “sobering discovery” that the traditional process of disk mastering produces sub-nanometer accuracy “took a while to realize”! The article proceeded with a quote by Loibl, comparing the accuracy required for disk mastering to microchip fabrication, concluding that chip manufacturing “is 5 – 10 times less precise than a cutting lathe.”

Loibl concluded that “Sometimes failure is necessary because it teaches us what doesn’t work. But with the huge amount of knowledge we’ve gained about vinyl production, we have a shortcut on future development.”

Interestingly, the aforementioned sobering discovery, complete with the comparison to chip manufacturing, had already been published in Copper on July 29, 2019 (Issue 90, “The Rise, Fall and Resurgence of the Vinyl Record”), perhaps demonstrating the immense research value Copper brings to the industry.

While I had written that piece, making $4.8 million worth of subsequent research revelations freely available to the public (I think this may be a strategic moment to request a pay raise), I cannot take credit for discovering any new information! That was merely the result of doing basic math on the most fundamental, long-established standards of disk recording, already published and peer-reviewed many decades ago.

Which begs the question: is the concept of conducting a literature review, before embarking on multi-million-dollar research, that much of a lost art?

After all, the invention of the smartphone (as an example for innovation) did not transpire out of thin air. The underlying principles were first developed in theoretical form in the 1930s, the operating system (Unix and its derivatives) has been in continuous development since 1969, and the various existing technologies were finally brought together into a single unit by industry giants with decades of relevant experience in the 2000s.

Most major departures from established industrial processes have resulted from continued development efforts aiming to maintain a competitive edge, by those who were well known for getting their hands dirty in their sector. The major developments in disk recording and manufacturing were primarily the result of efforts to develop or maintain competitiveness, by well-established players in the industry, with a long track record of innovation and the required engineering background. Developing an entirely new technology that would revolutionize an industry that has largely defied modernization in 130 years will probably need several decades of research and development, along with industry participation in every step of the process. Indeed, Loibl eventually realized that “the tools to achieve such a precision digitally will not be available for the next 15 – 20 years.” Which, in itself, is a good reminder to take aggressive marketing claims of the universal superiority of digital technology with a generous amount of skepticism.

However, if you were hoping to invest millions in vinyl record manufacturing technology, do not despair! A lot has been going on in the direction of much-needed infrastructure and technology in the industry, in line with its long history and conservatism, with no need to reinvent the wheel or depart from what has passed the test of time. New record presses are currently being made, along with new electroplating equipment, new disk mastering lathes, and new stylus manufacturing equipment, and there are discussions of starting a new lacquer manufacturing plant.

All of these are based on proven technology with small improvements where needed, developed by companies with the necessary collective wisdom/knowledge/experience among their workforce, with the functionality of the product routinely being demonstrated. HD Vinyl may have not brought a major revolution this time, but the good old vinyl record still reigns after 130 years of surviving relatively unmolested, still using the same technology and machinery used by our great-grandparents to manufacture and enjoy these time-defying historical artifacts. Vinyl encapsulates and preserves our achievements, our industrial development, our technical progress, and our cultural heritage, to be passed on, generation after generation in a single format that can be played back again and again, on new or vintage equipment that adheres to established standards. What other format can claim to have achieved as much?

Header image courtesy of Pixabay.com/davidfoxx.